1. About bubbles

1) What is a bubble?

2) Reasons for foam generation

(1) The use of surfactants;

(2) The use of polymer compounds;

(3) It has a certain defoaming ability, but the foaming speed is greater than the defoaming speed;

(4) Because the system is relatively When the system itself is thick, and stirring is used during production or processing, bubbles will be generated due to the entry of air;

(5) When a chemical reaction occurs in the system itself, some gas molecules are produced. This process is sometimes called degassing or absorption. Qi process.

3) Why defoaming

(1) causes the reaction materials to overflow the reactor, causing waste of raw materials and reducing production capacity;

(2) due to insufficient collision between raw materials, prolongs the reaction cycle;

(3) causes a decrease in product quality ;

(4) Resulting in passive operation and the generation of foam making production unable to proceed normally.

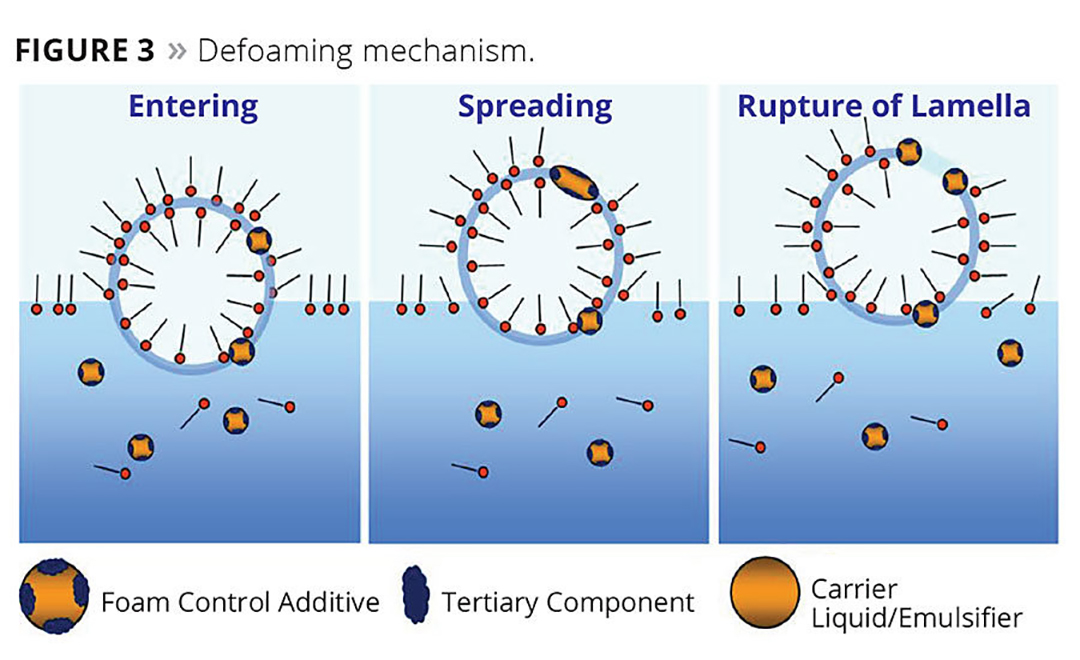

2. Defoaming mechanism: The defoaming agent has low surface tension and is easy to enter the liquid film and expand, reducing the surface tension of the liquid film, causing the liquid film to gradually become thinner, causing uneven internal stress and losing the ability to repair itself, causing it to rupture.

3. Classification, characteristics and composition of defoamer

1) Classification of silicone defoamer, polyether defoamer, mineral oil defoamer, fatty alcohol defoamer, solid defoamer

2) Characteristics of polyether defoamer It has excellent properties such as strong foam suppression ability and high temperature resistance. The disadvantage is that it has certain toxicity, the use conditions are limited by temperature, the foam breaking rate is not high, and the use area is narrow.Common glycerol polyether defoaming agents on the market can be roughly divided into GP type - polyoxypropylene glycerol polyether, GPE type - polyoxypropylene polyoxyethylene glyceryl ether and GPES type - polyoxypropylene polyoxyethylene glycerol polyether ester.Silicone defoamer is a liquid with particularly low surface tension containing polysiloxane as its main active ingredient.At the same time, fillers such as silica are added to form the main defoaming component, which can be prepared into emulsion defoaming agents and sol

3) Composition of active ingredients - the most important core part, which plays the role of breaking bubbles and reducing surface tension; representative substances: silicone oil, polyethers, higher alcohols, mineral oil, vegetable oil, etc.Emulsifier - disperses the active ingredients into small particles so that they can be better dispersed into oil or water and achieve better defoaming effect; Representative substances: non(octyl)phenol polyoxyethylene ether, soap salt, op series etc., Twain series, Span series, etc.

Representative substances: non(octyl)phenol polyoxyethylene ether, soap salt, op series, etc., Tween series, Span series, etc.Carrier - accounts for a large proportion of the defoaming agent, its surface tension is not high, it mainly plays the role of supporting medium, is beneficial to foam suppression and defoaming effects, and can reduce costs; Representative substances: solvents other than water, Such as aliphatic hydrocarbons, aromatic hydrocarbons, oxygenated solvents, etc.Emulsifying aids - make the emulsification effect better.Representative substances: dispersant: hydrophobic silica, etc.; tackifier: CMC, polyvinyl ether, etc.