About PDMS film

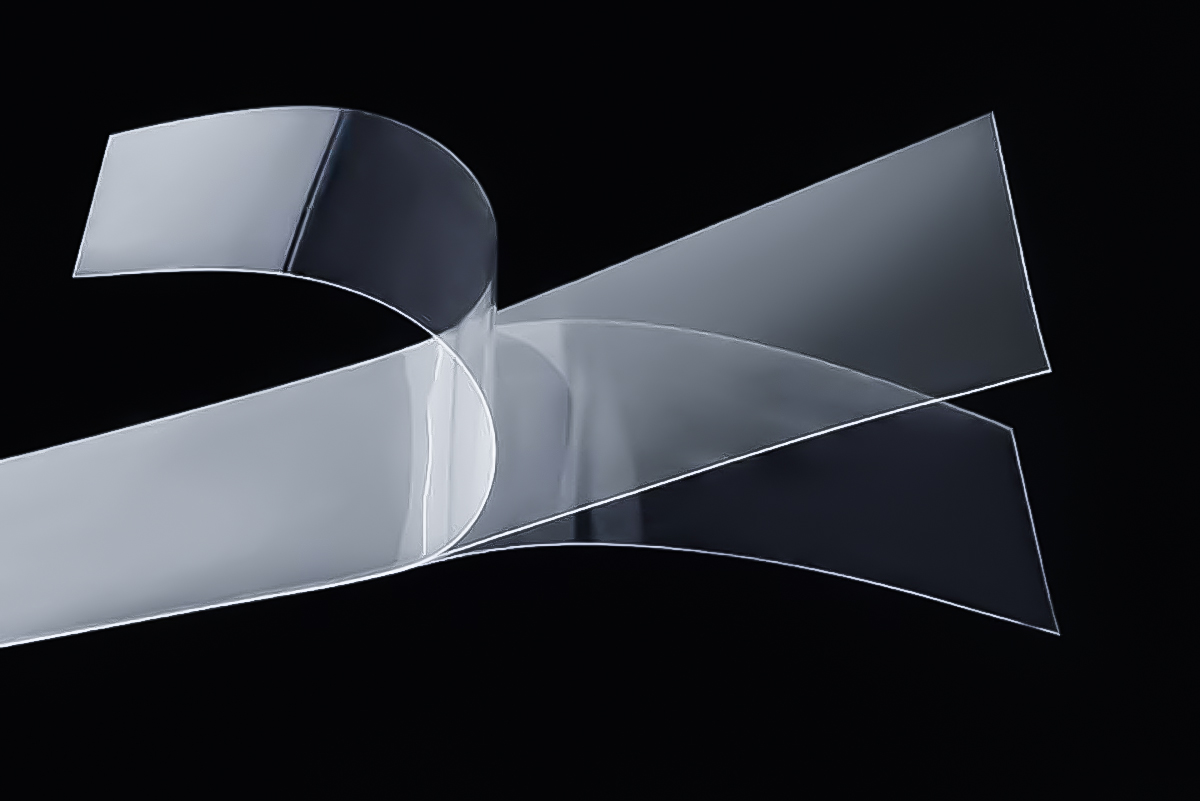

PDMS silicone film is a kind of high-resolution polymer film, which is prepared by special process with polydimethylsiloxane as raw material. Due to the characteristics of the polydimethylsiloxane material, the PDMS film is endowed with certain specific properties. Elasticity, low Young's modulus, excellent gas permeability, chemical stability, thermal stability, low temperature flexibility (excellent performance at -60~200°C), full transparency, biocompatibility. Since the PDMS film has the special properties that many of the above organic/inorganic films cannot have at the same time, this product has become the focus of research in recent years.

Development of PDMS at the present stage

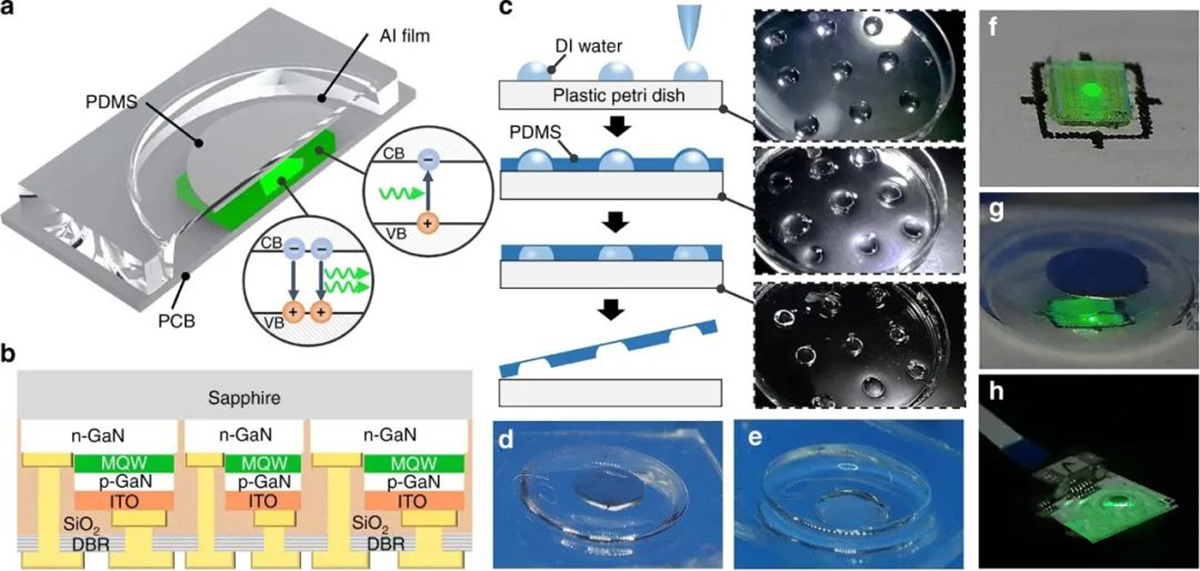

With the continuous development of electronic technology and material science, various smart electronics and flexible electronic devices have gradually come into people's attention, especially when BOE announced the mass production of China's flexible AMOLED production line, breaking Samsung's monopoly in this field. It is also a shot in the arm for major flexible electronic device research institutions and enterprises.

The prominent research fields in flexible devices should be flexible display, flexible sensing, wearable electronic products, electronic skin and other directions. In the realization of this series of flexible devices, the selection of new materials such as flexible dielectric materials, flexible conductive layers, and flexible electrodes has become a key step in product development.

At present, in the research of more flexible substrates and base materials, organosilicon polydimethylsiloxane (PDMS) has become the object of choice. It has the advantages of being convenient and easy to obtain, stable chemical properties, transparent and thermal stability, low Young's modulus, skin-friendly, and good adhesion to electronic materials. Two types of PDMS films KYN and KYQ independently developed and produced by our company can be applied to flexible device substrates.

Properties of PDMS thin films

1) The organic silicon film has good biocompatibility and is harmless to the human body, which is a safe and environmentally friendly product;

2) The silicone film is relatively soft, with good adhesion and comfortable touch;

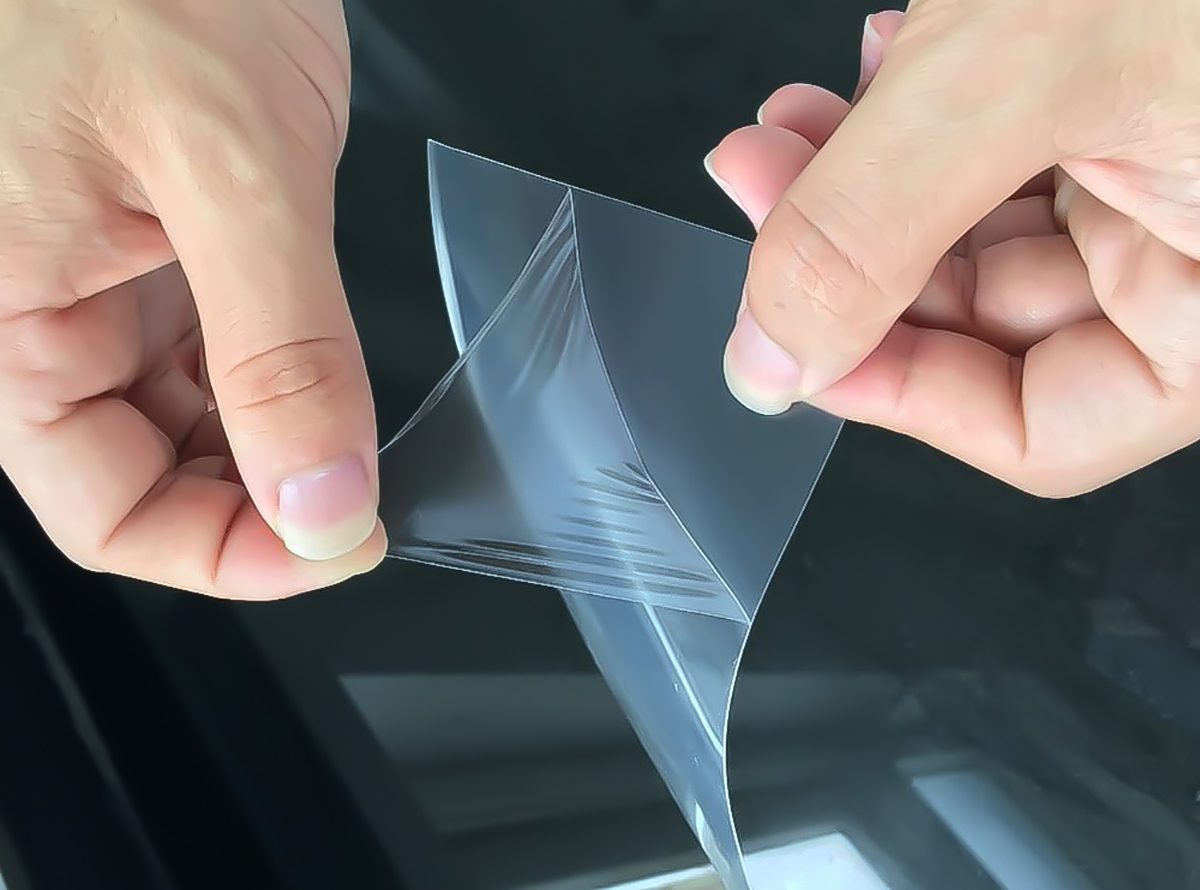

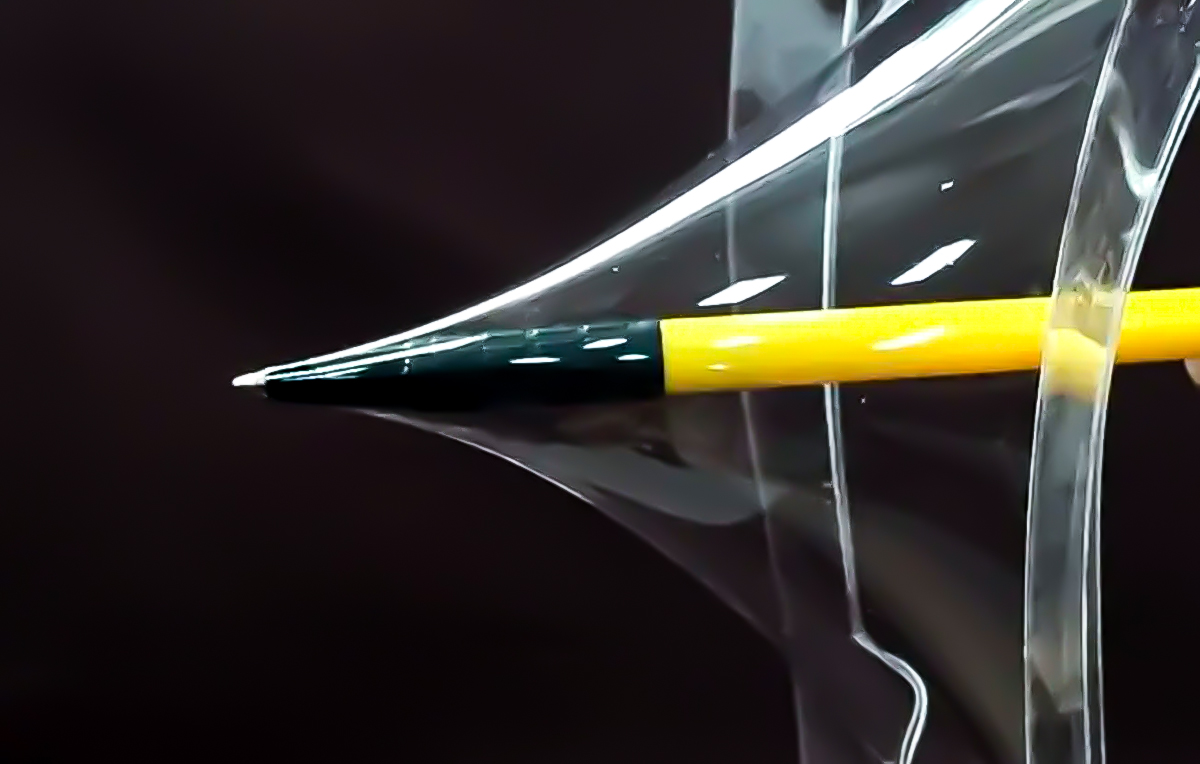

3) The film is elastic, and after being stretched for a certain length (as long as it is not broken), the film will return to its original shape without obvious deformation changes;

4) The elongation is better, within the range of 300~1000%

5) The product has good dielectric insulation, which is the choice of flexible substrate for the preparation of intelligent flexible electronic products;

6) The film is highly breathable, similar to human skin, and is the best choice for preparing robots, breathable band-aids (scar stickers), and gas separation.

Application of PDMS film

1) The air permeability of the film can be used for gas separation, such as the separation of small molecular gases such as gas, and the detection equipment gas permeates the film.

2) The tensile resilience of the film can be used as the insulating layer in the EAP dielectric elastomer, and can be designed and manufactured for actuators, sensors, etc.

3) Used in medical devices, making microfluidic chips, etc.

4) The surface of the film does not precipitate residues such as small molecules and is elastic, which can be used to protect high-value fragile products such as chips.

5) In addition, PDMS films can also be used in innovative applications such as artificial muscles, electronic skin, triboelectric power generation, and smart sensors.

PDMS membrane is a new supply form of silicone elastomer, and the material needs to be modified in combination with specific applications to adapt to more innovative applications.