Principles and types of viscometers: Viscosity is the physical quantity of internal friction that occurs in a fluid when it flows. It is the ability of the fluid to resist deformation and is an important indicator used to identify some finished or semi-finished products. Viscosity varies with fluid type and temperature. Generally, there are various types of viscometers. According to the operation mode, they can be divided into three types: rotary type, capillary type and vibration type. Let me introduce their differences and the differences in measurement principles.

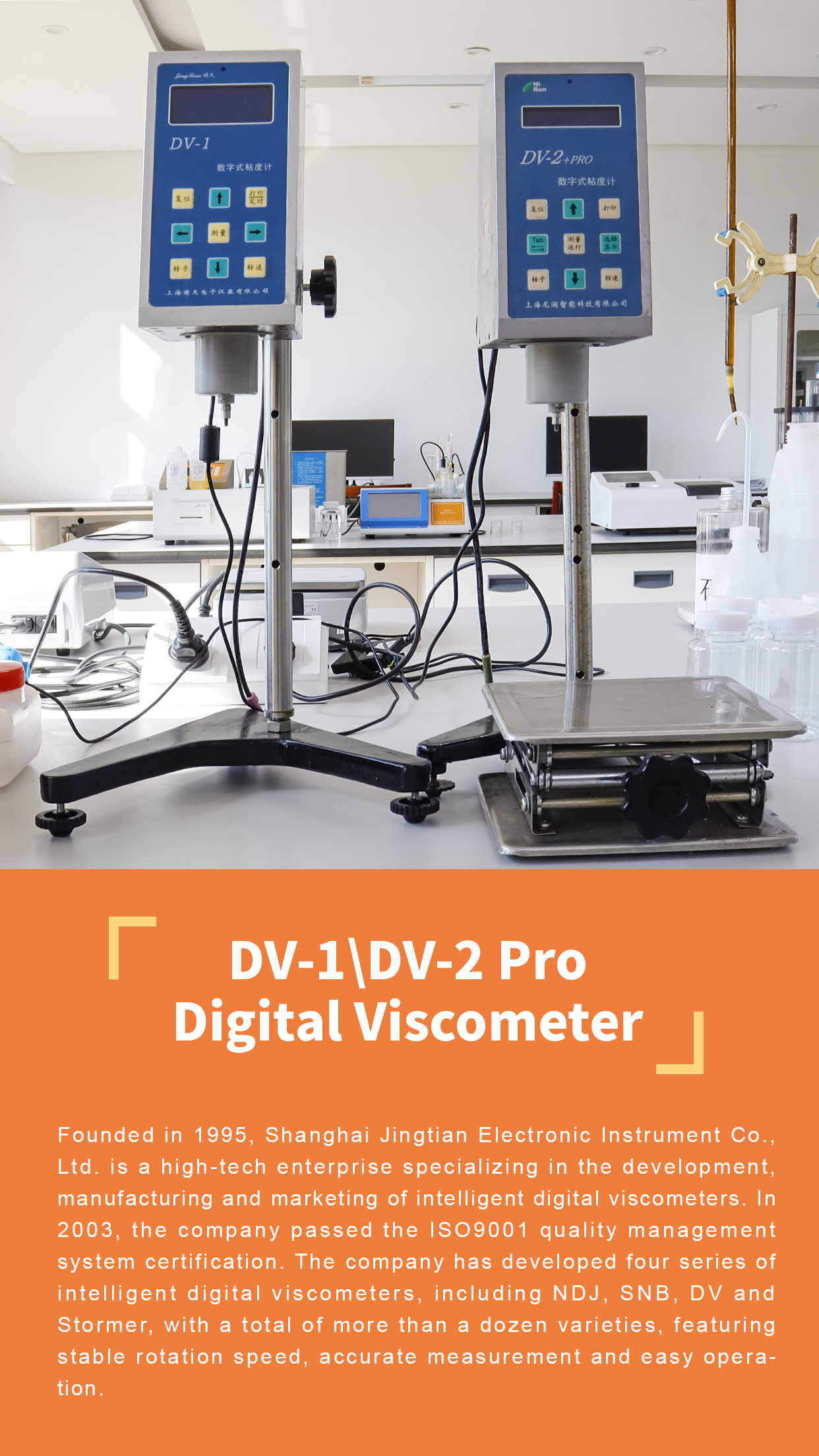

The first and most common type of rotational viscometer:

A common rotational viscometer is the cone and plate viscometer. Its basic principle is: a synchronous micro-motor drives the drum to rotate in the fluid to be measured at a certain rate. Due to the action of the fluid viscous force, the drum will lag, and the elastic element connected to the drum will A certain torsion is generated in the opposite direction of rotation, and the torsional stress is measured by the sensor to obtain the viscosity value of the fluid.

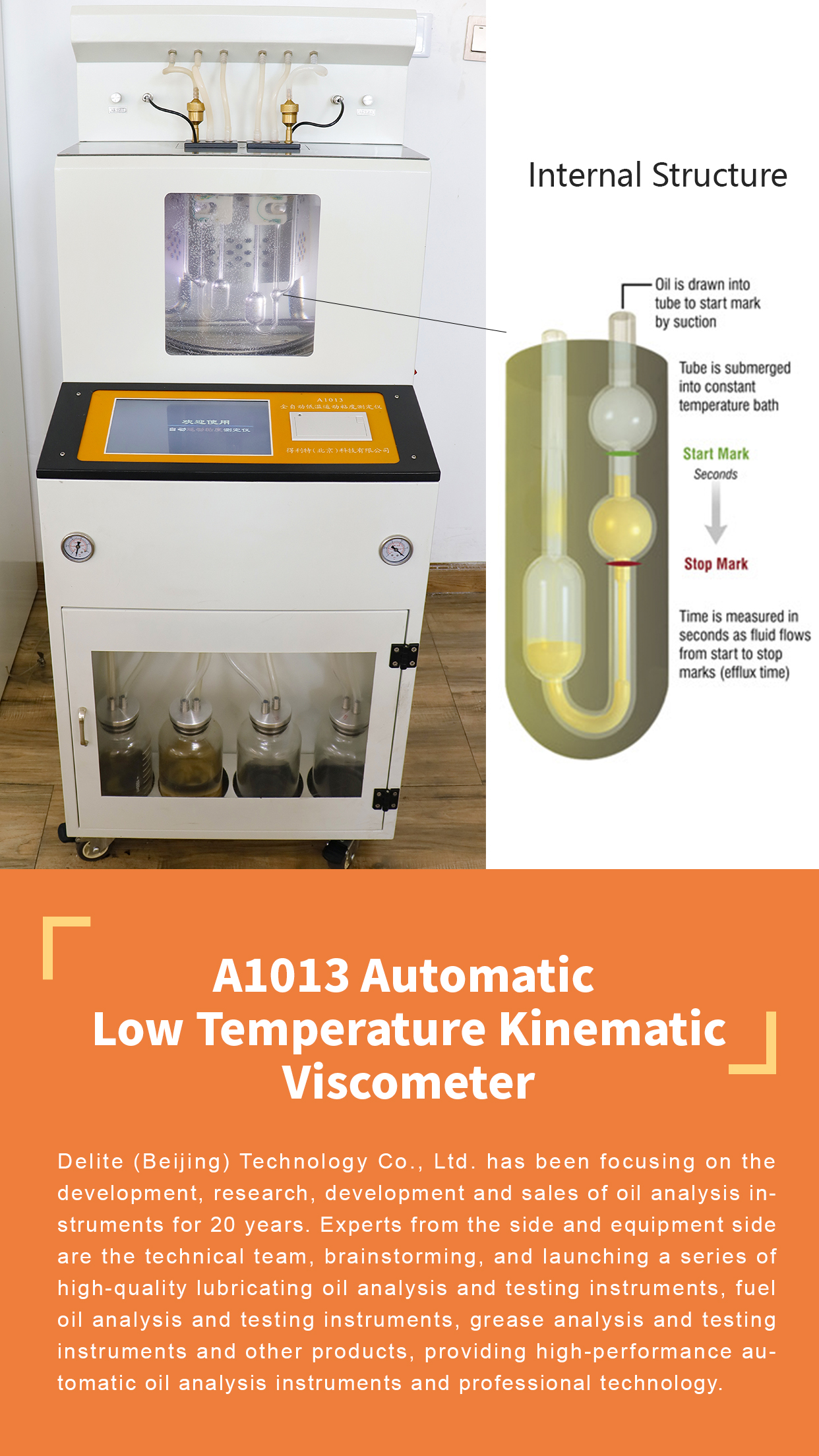

The second type of Ubbelohde viscometer

Ubbelohde viscometer generally refers to a three-tube instrument made of glass. It is an instrument that converts the time consumed by the gravity to return the fluid flowing through the distance of the scale line to the viscosity of the fluid under the action of external force. When the fluid flows under the action of external force, there is a tangential internal friction force between the flowing liquid layers. If the liquid is to pass through the pipe, a part of the work must be consumed to overcome the resistance of this flow. When the flow rate is low, the liquid in the pipe advances along a straight line parallel to the pipe wall. The liquid closest to the pipe wall is actually stationary, and the farther it is from the pipe wall, the greater the flow speed.

The third type, currently using the industry-leading Anton Paar automatic kinematic viscometer SVM 2001

Anton Paar (Anton Paar) has been established for 100 years, its company's instrument measurement technology is leading the world, its test results have reached SGS certification, and its test volume is small, fast and efficient. Well-calculated alternatives. No stopwatches or constant temperature baths are required to test samples, nor is there any need to calibrate a dozen glass capillaries one by one. Simple and fast viscosity measurements of all types of samples, including fuel oils, lubricating oils, and waste oils, are possible in the range of 15 °C to 100 °C. Simply fill the sample from the syringe and start measuring, with results in minutes. The entire viscosity range from 0.65 mm²/s to 30000 mm²/s can be covered with one measuring cell without changing the capillary, and the results of density, kinematic viscosity, kinematic viscosity can be obtained simultaneously.

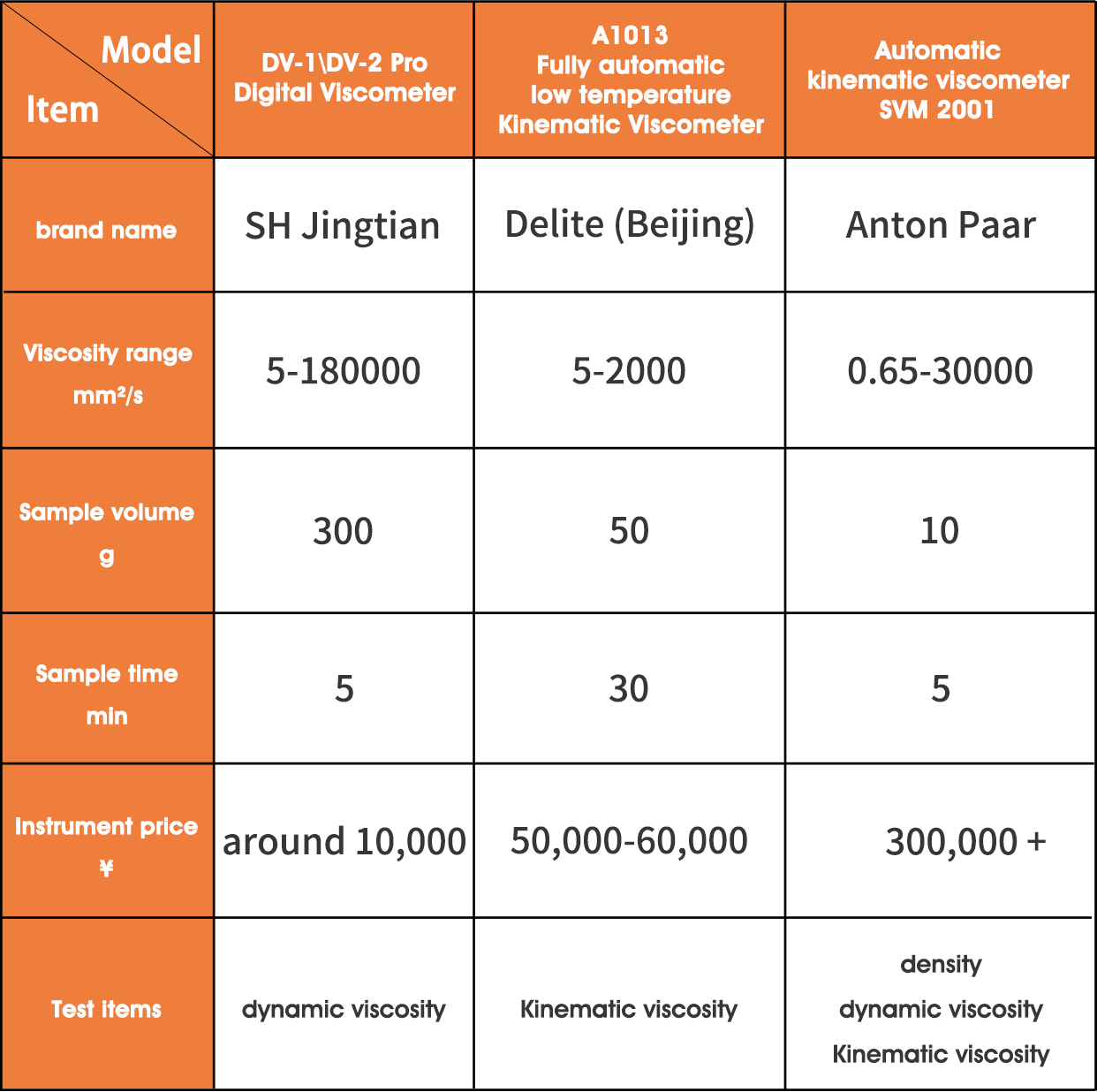

The parameters of these three viscometers are compared as follows: