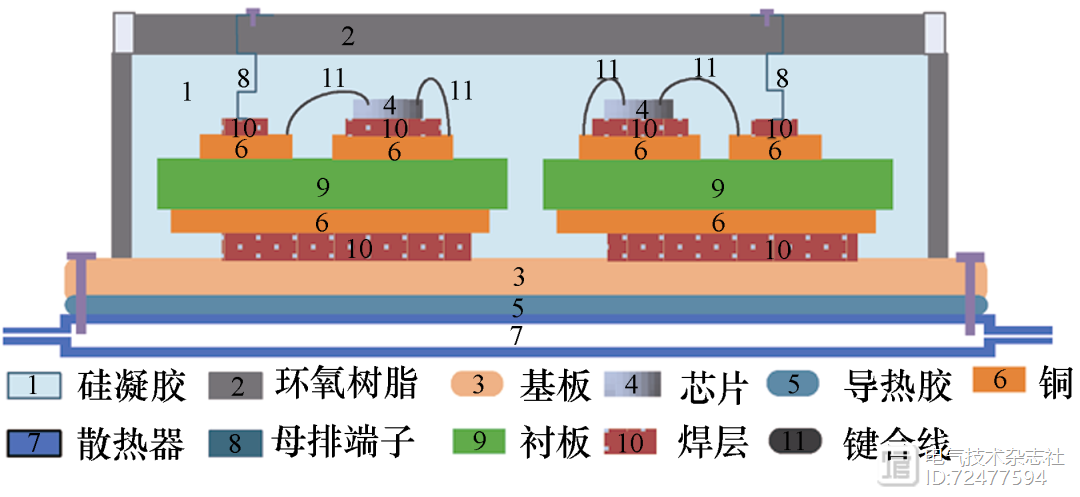

In the past ten years, insulated gate bipolar transistors (Insulated Gate Bipolar Transistor, IGBT) have made significant progress in terms of chip design, process, testing, and device packaging technology. In terms of device packaging, silicone gel materials have become indispensable packaging insulation materials for electronic devices because of their excellent temperature resistance, waterproof and electrical insulation properties. At present, the silicone gel used for encapsulation of silicon-based IGBT modules is a two-component addition type room temperature or heating vulcanization silicone gel.

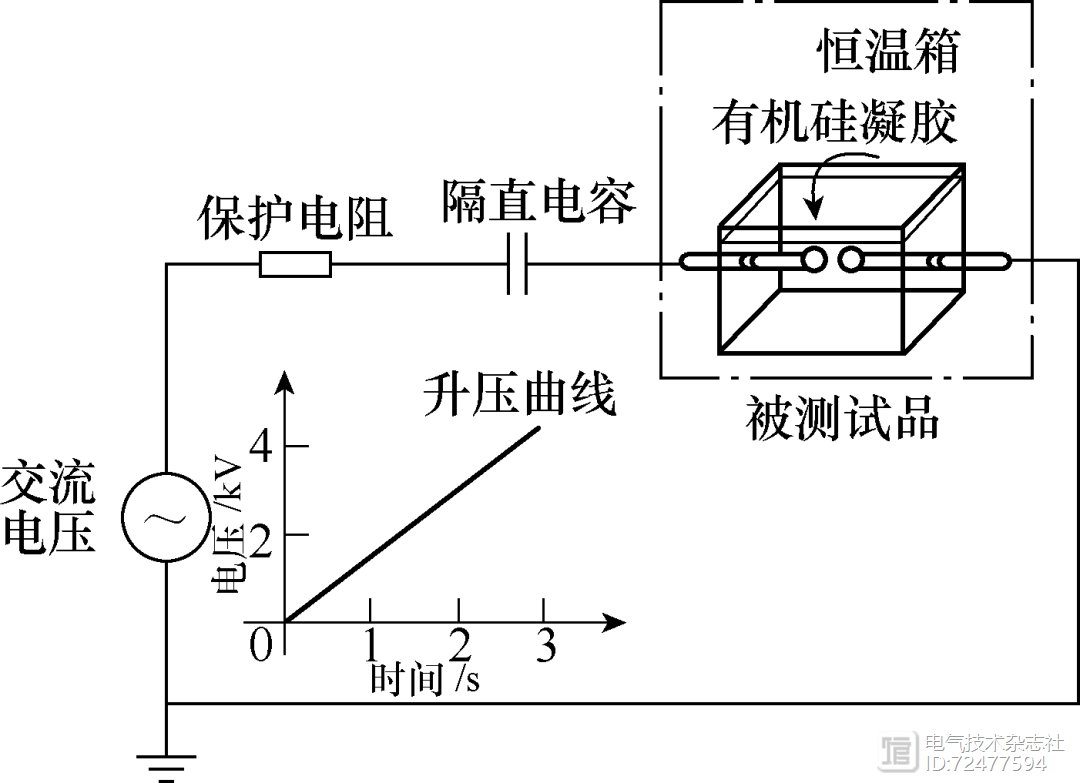

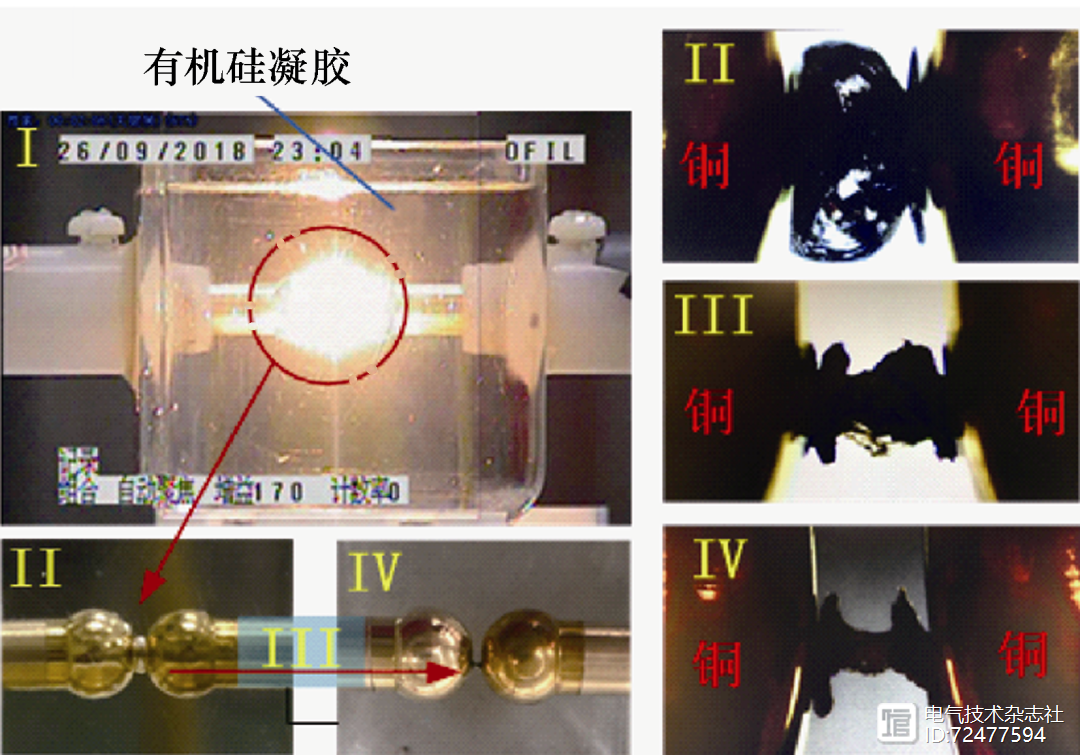

The breakdown characteristics of insulating materials directly reflect the insulation level of the material, and the breakdown field strength is a key electrical parameter to characterize the dielectric insulation characteristics. At present, although some studies have been carried out on the electrical resistance of silicone gels, the law and mechanism of the influence of temperature on the power frequency electrical resistance of silicone gel materials are still unclear.

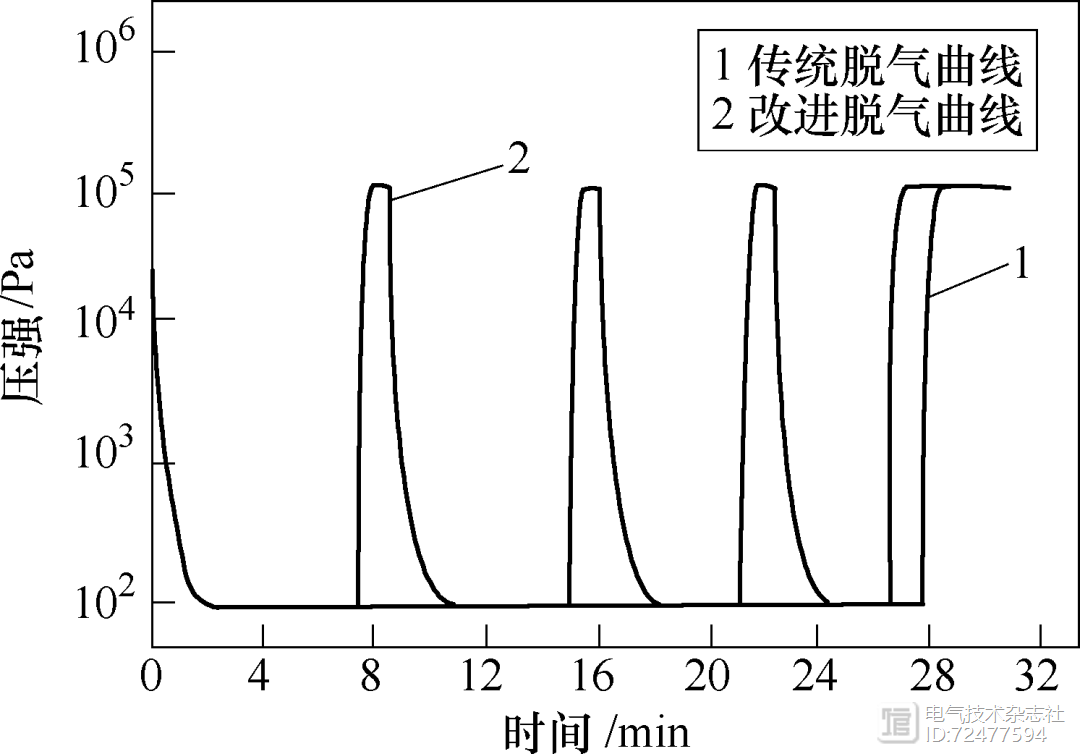

In response to the above problems, researchers from North China Electric Power University studied the potting process of silicone gel in detail, and proposed a new degassing curve to improve the preparation process of silicone gel for the problems existing in the application process of silicone gel , Improve the product quality of silicone gel.

In response to the above problems, researchers from North China Electric Power University studied the potting process of silicone gel in detail, and proposed a new degassing curve to improve the preparation process of silicone gel for the problems existing in the application process of silicone gel , Improve the product quality of silicone gel.

The researchers also analyzed the influence of temperature on the power frequency resistance characteristics of silicone gel. They found that within the test temperature range, the breakdown voltage of silicone gel decreased with the increase of temperature; and when the temperature reached 200 At ℃, the breakdown field strength decreases to 39.27kV/mm, which is about half of the breakdown field strength at room temperature.

The researchers tested the thermal properties of the silicone gel, and analyzed the mechanism of the influence of temperature on the power frequency resistance of the silicone gel. When the temperature rises, the free volume of the silicone gel increases, and the movement of molecular segments intensifies; and the internal carrier mobility of the silicone gel increases, and the leakage current increases, so after the temperature rises, the silicone gel The breakdown voltage is reduced.

This article is from the 2021 issue of "Journal of Electrotechnical Society" and the Journal of Electrical Technology. For academic sharing only.