In recent years, graphene has become the most concerned nanoelectronic device material due to its minimal thickness, transparency, high thermal and electrical conductivity, high mechanical strength, high aspect ratio, light weight, and good control over various functionalizations .

Furthermore, it effectively replaces earlier large-scale integrated circuit (IC)-based sensors, which are mostly semiconductors with a silicon substrate or matrix, and conductive metal nanoparticles deposited on them to form a continuous conductive path. However, the zero bandgap tunability of pristine graphene makes it different from semiconductors. There are several ways to open the band gap of multilayer graphene and its composites.

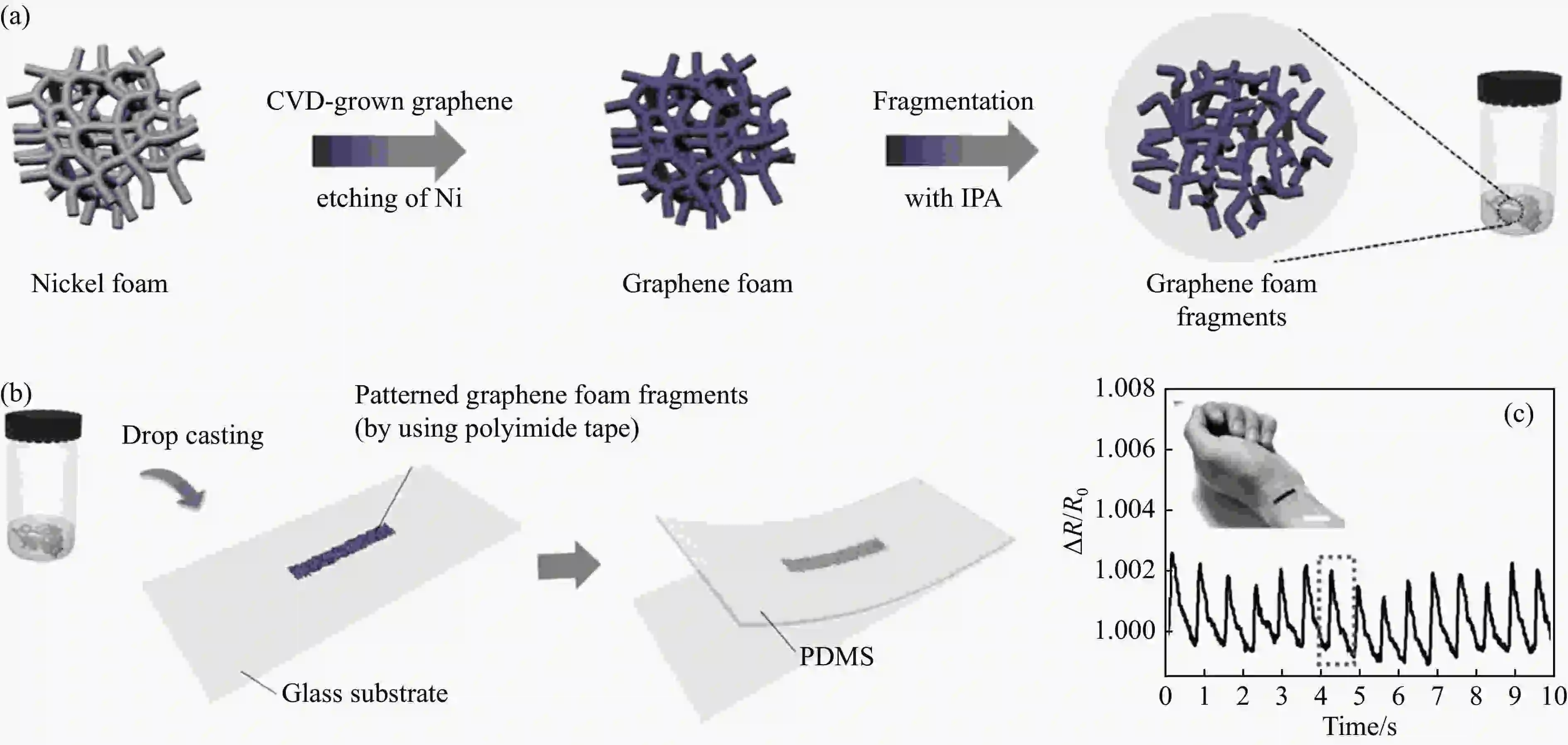

Flexibility is another desirable property of wearable electronics, which can be achieved by incorporating polymers. Polymers such as PDMS, polyethylene terephthalate (PET), polyethylene naphthalate (PEN) and polyimide (PI) are widely used in products requiring high flexibility and mechanical properties.

In addition, there are some conducting polymers such as polyaniline (PANI), polyacetylene (PA), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) , they require very little or no metal nanoparticles to form conductive pathways.

Among the above polymers, polydimethylsiloxane (PDMS) has similar properties, both of which are chemically inert, optically transparent, hydrophobic, and mostly biocompatible, so PDMS and graphene form composite materials . Furthermore, PDMS is known to form strong interfacial bonds with nanofillers. These composites could add a new dimension to currently available health bracelets, glucose sensors and smart watches for responsiveness and accuracy in monitoring the physiological state of the human body.

01. Nano powder of graphene

Graphene in nanopowder form maintains its excellent ion-carrying capacity. Furthermore, powdered graphene can be tuned by exploiting the high flexibility of its substrate without disrupting its conductive network. Laser-induced multifunctional graphene powders can be deposited on flexible PDMS/PI substrates to fabricate electrochemical sensors for glucose sensing.

Likewise, superelastic corrugated PDMS substrates with graphene nanopowders are also used for flexible strain sensors. Stretching and squeezing of the corrugated PDMS substrate under strain affects the electrical conductivity of the graphene powder network. Squeezing increases resistance, while stretching decreases it.

02. Reduced graphene oxide (rGO)

rGO is cheaper than pristine graphene, but differs only slightly in similar properties. The advantage of using rGO is its high specific surface area, which is crucial in absorption-based sensing applications. The larger the surface area, the higher the absorption of the target chemical or gas. This will improve the accuracy, linearity and cycle stability of the measurements.

In addition, it can also introduce more secondary sensing materials, thereby enhancing its multifunctional ability. Detection of glucose in sweat using rGO-coated silica (SiO2) nanospheres, glucose oxide, and Nafion solution deposited on carbon nanotube (CNT) and PDMS composite substrates. The chemiresistive gas sensor is made of rGO and zinc oxide (ZnO) nanorods.

03. Graphene Nanosheet (GNP)

GNPs are less than one micron in size and have an average density between 0.2 and 0.4 g/cm3. Compared with graphene nanopowders, GNPs are larger in size and thus exhibit high robustness and reproducibility. GNP/polycaprolactone (PCL) mixture masked with PDMS for chemiresistive detection of ethanol vapor. GNPs, platinum nanoparticles (Pt NPs), and silicone rubber composites can be used as polymer electrolyte membrane fuel cell catalysts.

04. Graphene quantum dots (GQD)

GQDs are graphene nanoparticles less than 100 nm in size. A GQDs/PDMS-based sensor was used to quantify the ovarian cancer biomarker CA-125 antigen. These sensors consist of amino-modified glass chips with a layer of 3-aminopropyltrimethoxysilane (APTMS)-functionalized GQDs that capture antibodies to the CA-125 antigen using a chemiluminescence resonance energy transfer process.