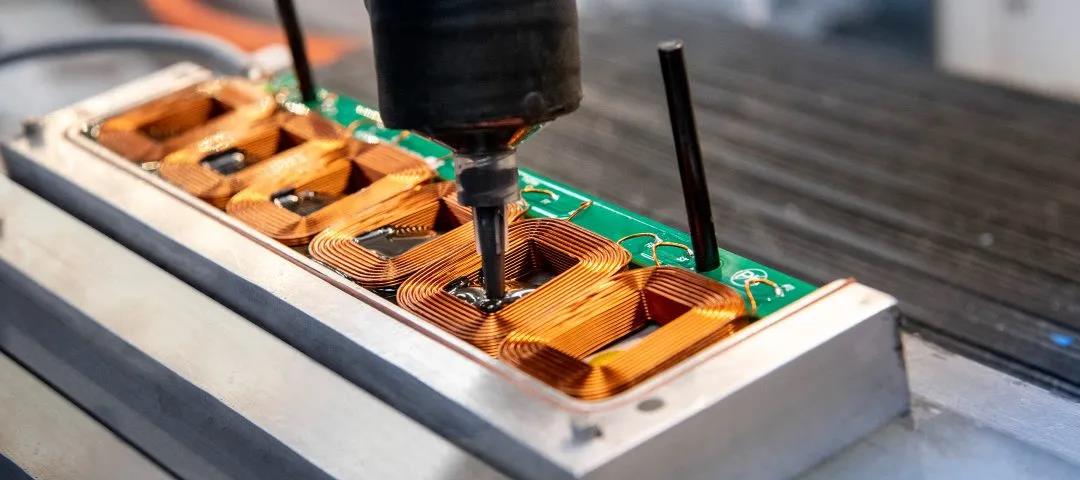

After the electronic products are manufactured, they often need to perform a potting process to isolate them from the outside world, so as to improve the shock resistance and waterproof performance of the electronic products, prevent the electronic components from being corroded by the natural environment, and prolong the service life of the electronic products. . At present, there are many kinds of potting materials used to infuse electronic components, and the most used are mainly: polyurethane materials, epoxy resin materials and silicone materials. Among them, the most used is silicone potting glue, which is widely used due to various excellent characteristics.

Organic silicon polymer materials have unique weather resistance, aging resistance, excellent high and low temperature resistance, good hydrophobic mechanical properties, electrical insulation, etc. due to the special silicon-oxygen bond main chain structure, so they are widely used in electronic appliances. Potting protection of components.

Characteristics of silicone

1) It has excellent resistance to high and low temperature. After curing, the silicone potting compound still maintains elasticity even if it withstands the thermal shock between -60℃~200℃.

2) It does not absorb or emit heat during curing, does not shrink after curing, will not have any effect on electronic components, and has good bonding performance.

3) It has excellent electrical properties and insulation properties, and is not corrosive to materials.

4) Strong thermal conductivity, effectively improving the heat dissipation capacity of electronic products.

5) It can be cured at room temperature or heated, which is easy to operate.

Common two-component addition forming silicone rubber potting compound: it is composed of vinyl-terminated silicone oil as the base rubber, hydrogen-containing silicone oil as the crosslinking agent, and aluminum oxide (AI2O3) as the thermally conductive filler. Methacryloxypropyltrimethoxysilane (KH570) can be added as a coupling agent, and a platinum catalyst (PL-2600) can be added as a catalyst.