When using dimethyl silicone oil to improve the hydrophobicity of PP matrix, viscosity is a key parameter. Its selection needs to consider the hydrophobic effect, compatibility with PP, processing technology and final performance requirements. The following are specific suggestions and analyses:

I. Core principle: Medium viscosity silicone oil is more suitable for PP systems

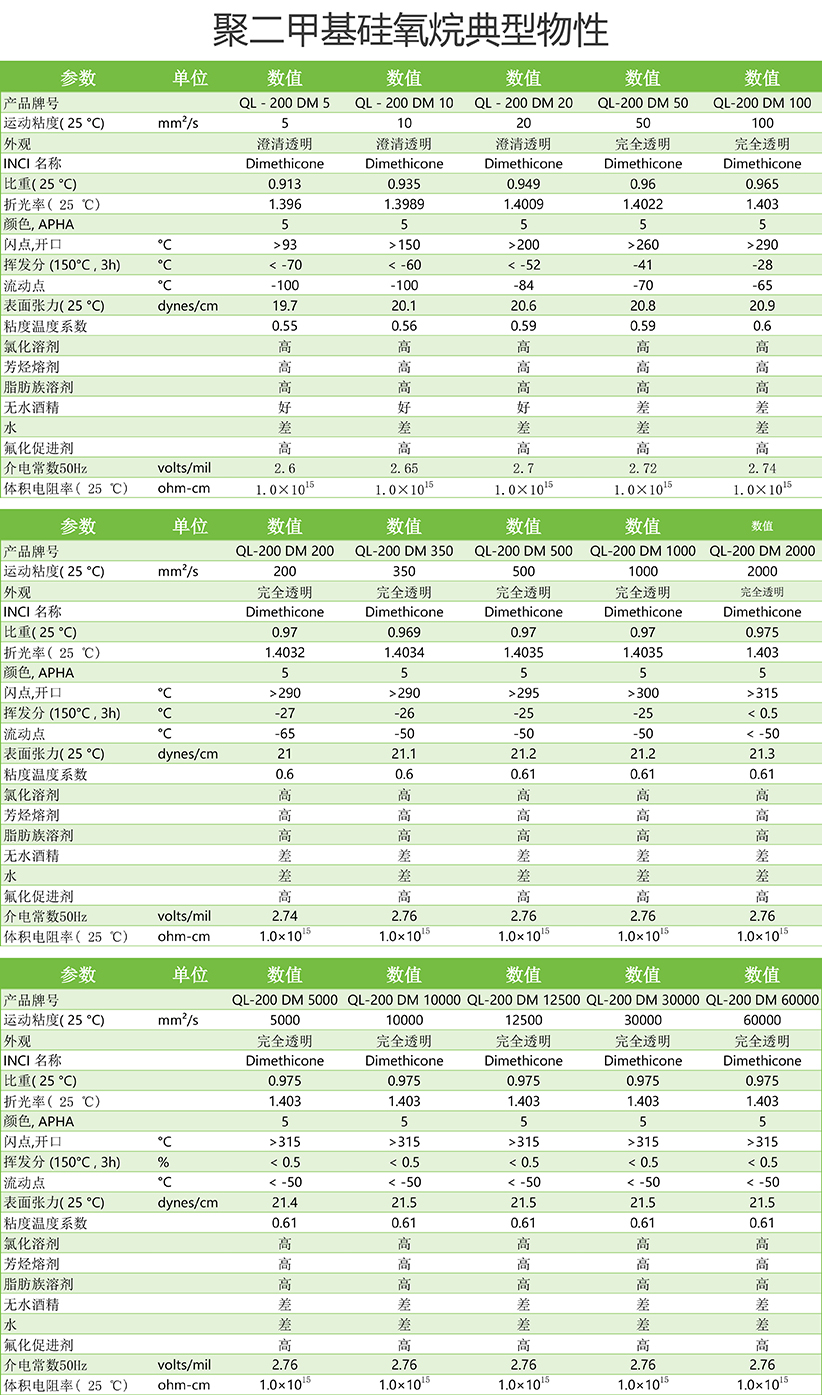

Considering the comprehensive effect and practicality, dimethyl silicone oil with a viscosity of 500-10000 cSt (centistokes) is recommended, among which 1000-5000 cSt is the most commonly used range.

- Low viscosity (<500 cSt): Too strong fluidity, easy to volatilize during processing or migrate too fast, leading to excessive surface enrichment (may cause stickiness);

- High viscosity (>10000 cSt): Poor fluidity, difficult to disperse uniformly in PP matrix, easy to agglomerate, which may reduce the uniformity of hydrophobicity.

II. Applicability analysis of silicone oil with different viscosities

| Viscosity range (cSt) | Characteristics and applicability | Hydrophobic effect | Compatibility with processing technology |

|---|---|---|---|

| 100-500 | Excellent fluidity and easy to disperse, but high volatility (especially during high-temperature processing), easy to exude from PP and cause surface stickiness. | The initial contact angle increases significantly (110°-115°), but the long-term effect is unstable (due to too fast migration). | Suitable for surface coating (quick film formation), not suitable for melt blending (easy to lose). |

| 500-5000 | Moderate fluidity, good dispersibility when melt blended with PP, controllable migration rate (slowly migrate to the surface to form a stable hydrophobic layer), low volatility. | The contact angle is stably maintained at 110°-120°, with long-lasting hydrophobic effect and no obvious stickiness. | Suitable for melt blending (injection molding, extrusion) and is the most commonly used choice. |

| 5000-10000 | Higher viscosity, decreased fluidity, requiring stronger shear force for uniform dispersion, slow migration rate, and slower surface enrichment rate. | The contact angle is slightly lower than that of low-viscosity oil (105°-115°), but the hydrophobic layer is more stable and not easy to fall off. | Suitable for scenarios with slightly higher mechanical performance requirements (less impact on strength when added in excess). |

| >10000 | Thick like paste, decreased compatibility with PP, easy to form "island-like" agglomeration, resulting in uneven surface hydrophobic performance (too high in some areas, no effect in others). | Unstable effect, possible fluctuation in contact angle (95°-110°). | Not recommended for 单独使用,can be mixed with a small amount of low-viscosity silicone oil to adjust fluidity. |

III. Selection suggestions: Matching viscosity according to processing methods

-

Melt blending (mainstream method)

- Priority is given to 1000-3000 cSt: Silicone oil in this range has moderate fluidity in the molten state of PP (180-220℃), is easy to disperse uniformly through screw shear, and can slowly migrate to the surface after product forming to form a continuous hydrophobic layer, balancing effect and stability.

- Example: Adding 1%-3% 3000 cSt silicone oil to PP injection molded products (such as containers and pipes) can stabilize the water contact angle at about 115° without surface stickiness.

-

Surface coating

- Choose 500-1000 cSt: Low viscosity is easier to spread into a film, quickly forming a highly hydrophobic surface (contact angle can reach 120° instantly). However, it is necessary to mix with a tackifier (such as silane coupling agent) to improve adhesion to the PP surface, otherwise it is easy to fall off.

-

Composite modification (compounded with nanoparticles)

- Use 3000-5000 cSt: Higher viscosity can wrap nanoparticles (such as SiO₂), reduce agglomeration, and jointly build a synergistic hydrophobic system of "micro-nano structure + low surface energy", with the contact angle can be increased to more than 120°.

IV. Notes

- Viscosity is not the only indicator: It is necessary to pay attention to the purity of silicone oil (low volatile models are better to avoid volatile loss during processing) and molecular weight distribution (silicone oil with narrow distribution has more stable performance).

- Test verification: Different PP grades (such as homopolymer PP and copolymer PP) have slightly different crystallinity and polarity. It is recommended to conduct small-scale tests first (such as adding 1%, 2%, 3% of silicone oil with different viscosities), and determine the best scheme through contact angle measurement and surface state observation (whether it is sticky, whether it is uniform).

Summary: For improving the hydrophobicity of PP, dimethyl silicone oil with a viscosity of 1000-3000 cSt is the most cost-effective choice, especially suitable for melt blending processes. It can ensure hydrophobicity (contact angle 110°-120°) while avoiding surface stickiness and degradation of mechanical properties.