Viscosity selection principle

The viscosity of dimethyl silicone oil (usually expressed as kinematic viscosity (cSt) at 25°C) should be selected in combination with the temperature range, heat dissipation requirements, equipment fluidity requirements and other factors of the specific use scenario. Common references are as follows:Low temperature environment/low load scenario (such as -40°C~100°C):Recommended low viscosity models, such as 20cSt, 50 cSt, 100 cSt.

Features: Good fluidity, not easy to solidify at low temperature, suitable for equipment that requires rapid heat dissipation and low resistance flow (such as cooling of small electronic components).

Medium temperature environment/conventional heat dissipation (such as 100°C~200°C):Commonly used 200 cSt, 300 cSt, 500 cSt.

Features: Balanced fluidity and lubricity, suitable for conventional cooling of most industrial and electronic equipment, and has certain wear resistance.

High temperature/high load scenario (such as above 200°C or high shear environment):Select high viscosity models, such as 1000 cSt and above.

Features: Strong stability at high temperature, high oil film strength, can effectively reduce equipment wear, suitable for high-temperature operation of machinery or precision instruments cooling.

Note: Avoid too low viscosity resulting in insufficient heat dissipation efficiency or lubrication failure, or too high viscosity resulting in poor fluidity and heat dissipation obstruction. In practical applications, it is recommended to optimize viscosity selection through testing.

Main industry applications

Electronics and semiconductor industry:

Uses: cooling and insulation of power modules, LED heat dissipation, transformers, capacitors, and high-temperature cooling of chip manufacturing equipment.

Advantages: high insulation, low volatility, avoid electrical breakdown or contamination of precision components.

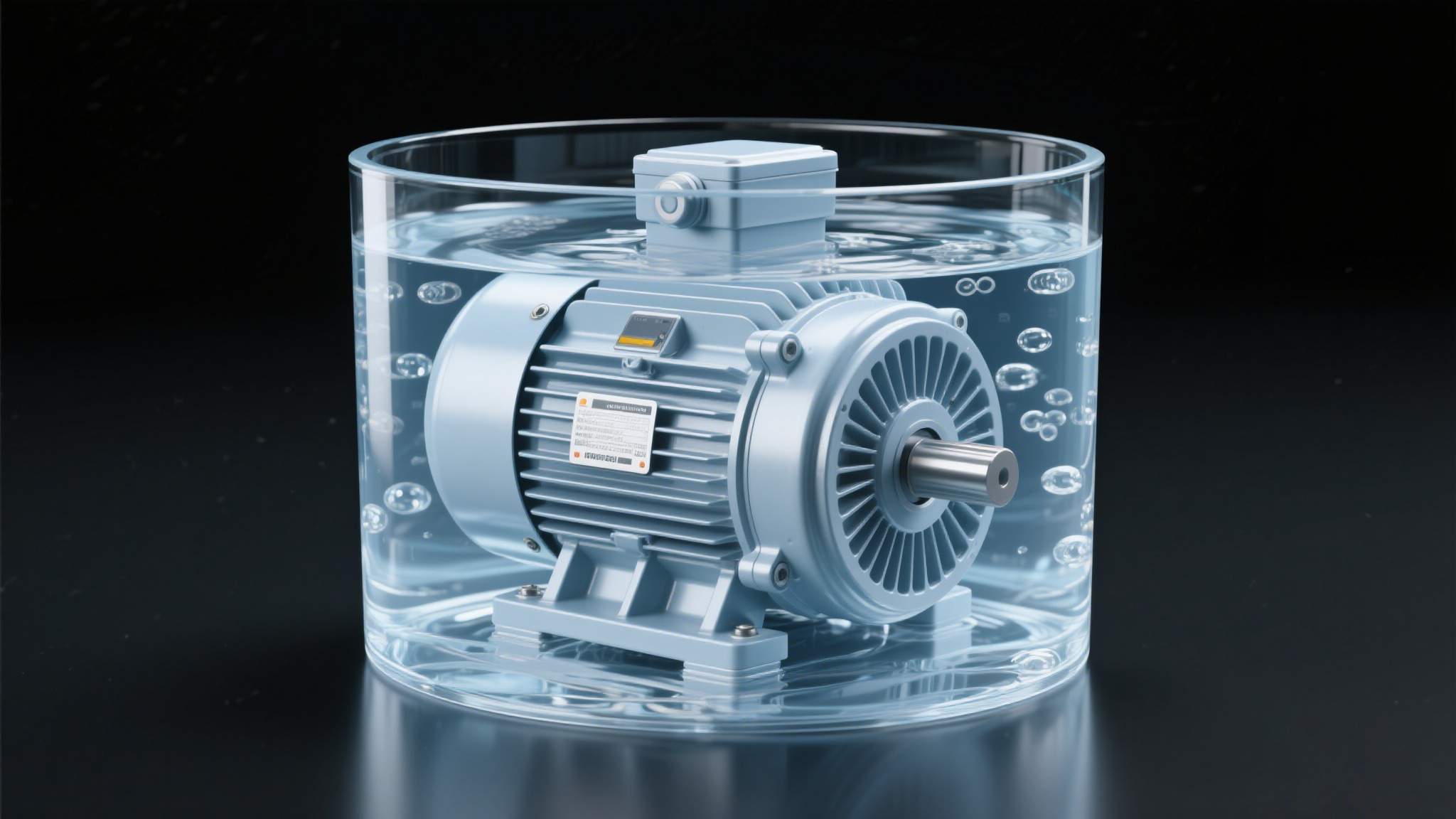

Electrical equipment industry:

Uses: cooling and insulation of motors, relays, and high-voltage switches, especially suitable for high temperature, high humidity or dusty environments.

Advantages: strong chemical stability, aging resistance, and stable performance in long-term use.

Automobile and machinery manufacturing:

Uses: automobile engine oil coolers, gearbox cooling media, cooling and lubrication of industrial machinery hydraulic systems, and heat dissipation of high-temperature bearings.

Advantages: high and low temperature resistance (-50℃~250℃), shear resistance, and reduced wear of mechanical parts.

Aerospace and military industry:

Uses: cooling of aircraft engine components, heat dissipation of electronic components in missile guidance systems, and equipment protection in extreme temperature environments.

Advantages: wide temperature range adaptability, low volatility, and compliance with stringent reliability requirements.

Medical and food industry (food grade certification required):

Uses: cooling of medical equipment (such as dialysis machines, surgical instruments), lubrication and cooling of high-temperature components of food processing machinery.

Advantages: non-toxic, non-corrosive, and in line with hygiene standards (such as food-grade silicone oil certified by the US FDA).

New energy field:

Uses: cooling of lithium battery production equipment, heat dissipation of photovoltaic inverters, and medium cooling of fuel cell stacks.

Advantages: resistance to electrochemical corrosion, low dielectric constant, and adaptation to the high power density requirements of new energy equipment.

Summary

Dimethyl silicone oil has become an ideal choice for cooling high-temperature/precision equipment in many industries due to its excellent thermal stability, insulation and chemical inertness. Viscosity selection requires a comprehensive evaluation of temperature, load, and fluidity requirements, while industry applications cover electronics, automobiles, aviation, medical and other fields with high requirements for reliability and environmental adaptability. In actual use, it is recommended to refer to the equipment manufacturer's specifications or determine the best solution through performance testing.