Thermal conductive fillers, as the name implies, are fillers added to the base material to increase the thermal conductivity of the material. Commonly used thermal conductive fillers include aluminum oxide, magnesium oxide, zinc oxide, aluminum nitride, boron nitride, silicon carbide, etc. Among them, micron-grade aluminum oxide and silicon micropowder are the main materials, and nano-aluminum oxide and nitride are used as filling powders in the field of high thermal conductivity; while zinc oxide is mostly used as a filler for thermal conductive paste (thermal conductive silicone grease). Thermal conductive silicone grease is a thermal conductive organic silicone grease-like compound made by adding heat-resistant and excellent thermal conductive fillers, commonly known as heat dissipation paste.

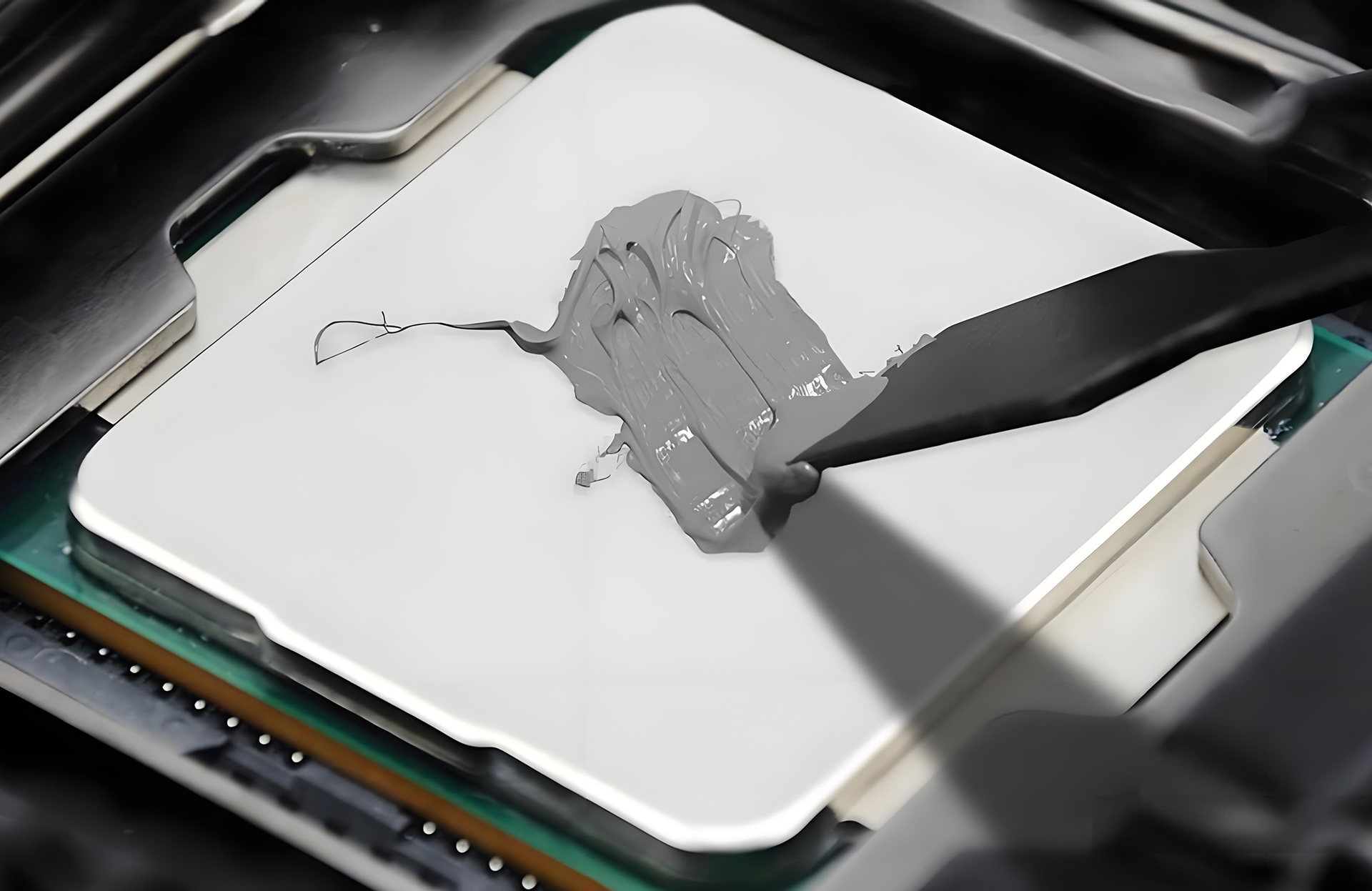

Thermal grease is also called thermal conductive silicone grease, silicone paste, thermal conductive paste or thermal paste. It is a paste-like high-efficiency heat dissipation product with no adhesive properties and will not dry out. It is produced using a special formula and filled between the heat source and the radiator. It also has multiple properties such as thermal conductivity/insulation, which can fully lubricate and protect the contact surface, thereby forming a very low thermal resistance interface, which is much more efficient than the air conduction between the contact surface of the heat source and the radiator. It is made of metal oxides with good thermal conductivity and insulation and organic siloxane. The product has good thermal conductivity, good electrical insulation, a wide operating temperature (working temperature -60℃ ~ 300℃), good stability, low viscosity and good construction performance. This product is non-toxic, non-corrosive, odorless, non-drying and insoluble.

Product Features

1. After surface modification, the high thermal conductivity silicone grease filler (DCZ) has nano-thickness, low oil absorption value, good compatibility with silicone oil, and excellent scraping properties of the product;

2. The high thermal conductivity silicone grease filler product has high purity and reasonable particle size. It can be added to the substrate to a large extent to form a dense thermal conductivity network path and build a phonon heat transfer channel;

3. The high thermal conductivity silicone grease filler (DCZ) has a wide range of applications and can be used to prepare high thermal conductivity silicone grease products of 3.5-6.5W/m.K and above;

4. High thermal conductivity silicone grease filler (DCZ) belongs to the category of inorganic thermal conductive ceramics, so it meets the EU environmental protection standards and is an inorganic environmentally friendly high thermal conductivity filler.

From the basic performance point of view, heat dissipation silicone grease is generally made of special silicone oil as the base oil, new metal oxides as fillers, and a variety of functional additives. It is a paste of different colors processed by special processes.

The composition is silicone oil + filler, and the thermal conductive filler is nano-alumina powder, and the composition is ZnO/Al2O3/boron nitride/silicon carbide/aluminum powder, etc. Silicone oil ensures a certain fluidity, and the filler fills the tiny gap between the CPU and the radiator to ensure thermal conductivity. Since silicone oil is less sensitive to temperature, it does not thicken at low temperatures, does not become thinner at high temperatures, and does not volatilize, so it can be used for a relatively long time. Now some thermal conductive silicone greases use silver powder or aluminum powder as fillers, which utilizes the high thermal conductivity of metals.

The filler of thermal conductive silicone grease is a finely ground powder, and the composition is: boron nitride/silicon carbide/aluminum powder/silver powder, etc. Silicone oil ensures a certain fluidity, and the filler fills the tiny gap between the heat source and the radiator to ensure thermal conductivity. Since silicone oil is less sensitive to temperature, it does not thicken at low temperatures, does not become thinner at high temperatures, and does not volatilize, so it can be used for a relatively long time.