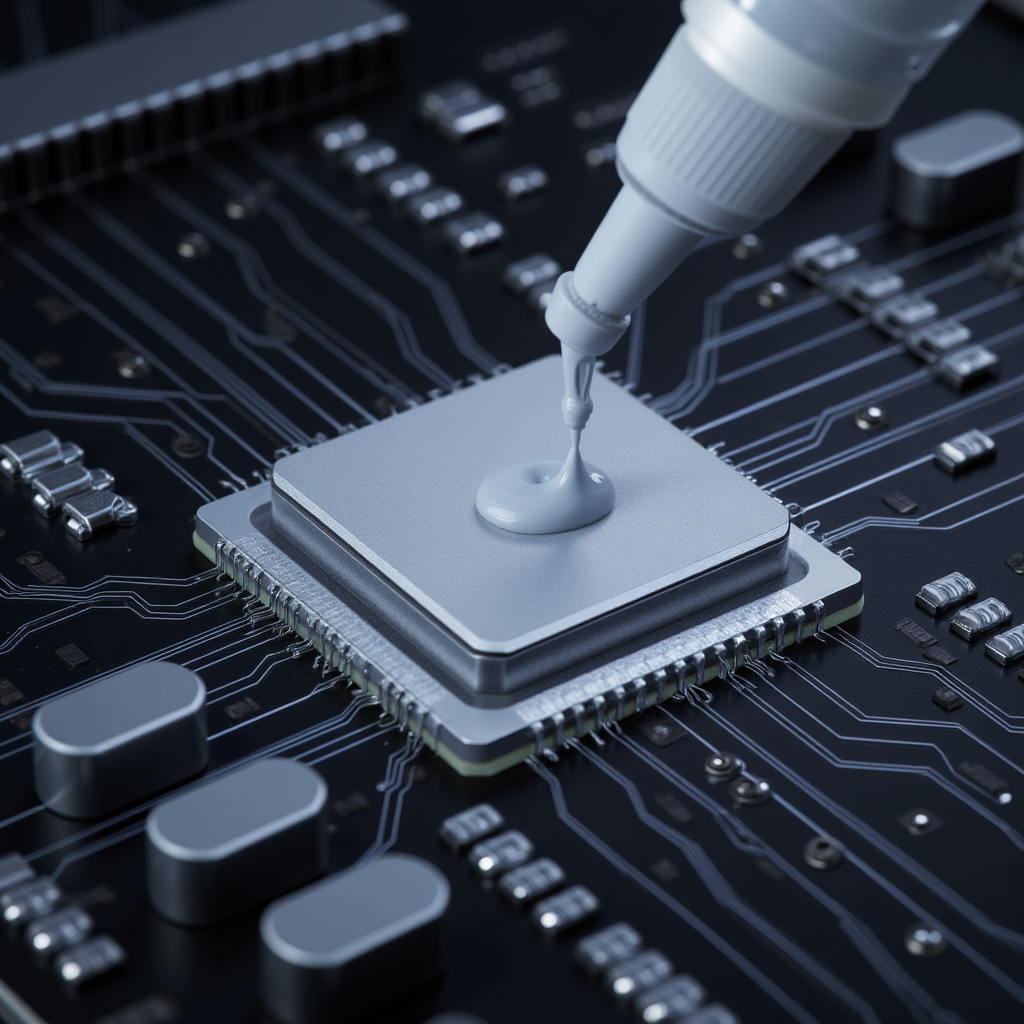

Silicone grease, the full name of which is thermal conductive silicone grease, commonly known as thermal paste or heat dissipation paste, is a paste made of special silicone oil as the base oil, mixed with new metal oxides and other functional additives, and processed by a specific process.

Ingredients and Appearance: Silicone grease is usually white or other colors, and the specific color varies depending on the material. It uses silicone oil as the base oil, mixed with metal oxide powders such as aluminum oxide and zinc oxide, and the overall appearance is mostly gray and non-conductive.

This article will conduct an in-depth discussion on the basic principles of silicone grease, factors affecting consistency, methods for regulating consistency, and application examples.

The basic principle of silicone grease

Silicone grease is a composite material made of silicone oil (polydimethylsiloxane) and thickener (such as silica). Silicone oil provides lubrication and thermal conductivity, while thickener gives it the required consistency and stability. The consistency of silicone grease is an important physical property of silicone grease, which directly affects its performance in different application scenarios. Silicone grease with lower consistency has better fluidity and is suitable for occasions that need to cover large areas or fill fine gaps; silicone grease with higher consistency has stronger adhesion and mechanical stability, and is suitable for occasions that require higher load-bearing capacity and longer service life.

Factors affecting the consistency of silicone grease

1. Viscosity of silicone oil

The viscosity of silicone oil is the basic factor that determines the consistency of silicone grease. Low-viscosity silicone oil has strong fluidity and the silicone grease made is relatively thin; high-viscosity silicone oil has poor fluidity and the silicone grease made is thicker. By selecting silicone oils of different viscosities, the consistency of silicone grease can be initially controlled.

2. Type and amount of thickener

The role of thickener in silicone grease is similar to that of a "skeleton", and its type and amount directly affect the consistency and structure of silicone grease. Commonly used thickeners include silica, bentonite, metal soap, etc. Silica is widely used in the formulation of silicone grease due to its good thermal stability and chemical inertness. An increase in the amount of thickener usually increases the consistency of silicone grease, but it also affects its rheological properties and thermal conductivity.

3. Use of additives

In addition to silicone oil and thickeners, other functional additives may be added to the silicone grease formula, such as antioxidants, preservatives, thermal conductive powders, etc. These additives can not only improve the performance of silicone grease, but also have a certain effect on its consistency. For example, the addition of thermal conductive powder can increase the consistency of silicone grease while improving thermal conductivity.

4. Mixing and processing technology

The mixing and processing technology of silicone grease also has a significant impact on its consistency. Uniform mixing can ensure that the silicone grease has a consistent consistency, while improper processing technology may cause the silicone grease to have an uneven consistency or stratification. Common mixing processes include mechanical stirring, grinding, and ultrasonic dispersion.

Methods for regulating the consistency of silicone grease

1. Adjusting the viscosity of silicone oil

The consistency of silicone grease can be directly affected by selecting silicone oil of different viscosities. For example, thermal conductive silicone grease commonly used in electronic products generally uses low-viscosity silicone oil to ensure its good fluidity and thermal conductivity; while in industrial greases that require high mechanical strength and wear resistance, high-viscosity silicone oil is more likely to be used.

2. Selecting the appropriate thickener and its dosage

Choosing the appropriate thickener type and dosage according to specific application requirements is an important means of regulating the consistency of silicone grease. For example, for silicone grease used in high temperature environments, silica with good thermal stability can be selected as a thickener, and its dosage can be adjusted to achieve the desired consistency and performance.

3. Adding functional additives

Adding an appropriate amount of functional additives to the silicone grease formula can fine-tune the consistency and performance of the silicone grease without significantly changing the ratio of silicone oil and thickener. For example, adding a small amount of thermal conductive powder such as nano-alumina or zinc oxide can increase the consistency of the silicone grease while improving thermal conductivity.

4. Optimize mixing and processing technology

By optimizing the mixing and processing technology, the consistency uniformity and stability of silicone grease can be improved. For example, high shear mixing or grinding process can make the thickener dispersed more evenly in the silicone oil, thereby improving the consistency and stability of silicone grease.

Application examples of silicone grease consistency control

1. Heat dissipation of electronic equipment

In electronic equipment, silicone grease is mainly used as a heat transfer medium to transfer the heat generated by electronic components to the radiator or heat sink. In such applications, the consistency of silicone grease should be moderate to ensure its good filling and thermal conductivity. By selecting low-viscosity silicone oil and an appropriate amount of thermal conductive powder, a thermal conductive silicone grease with moderate consistency and excellent thermal conductivity can be prepared.

In the automotive industry, silicone grease is often used to lubricate components such as door hinges, window rails, and seat rails. In such applications, silicone grease needs to have high mechanical stability and wear resistance to ensure that it can still maintain good lubrication effect under high load and long-term use. By selecting high-viscosity silicone oil and an appropriate amount of metal soap thickener, a lubricating silicone grease with high viscosity and excellent mechanical strength can be prepared.

3. Medical device lubrication

In medical devices, silicone grease is mainly used as a lubricating and sealing material, such as syringes, catheters, and joint prostheses. In such applications, silicone grease not only needs to have a suitable viscosity, but also needs to be biocompatible and chemically inert. By selecting medical-grade silicone oil with appropriate viscosity and a biocompatible thickener, silicone grease that meets the requirements of medical devices can be prepared.

4. Industrial sealing and insulation

In the industrial field, silicone grease is often used in sealing and insulating applications, such as cable connectors, sealing rings, and high-voltage switches. In such applications, silicone grease needs to have good sealing, high temperature resistance, and electrical insulation properties. By selecting silicone oil with appropriate viscosity and a silica thickener with excellent thermal stability, a sealing and insulating silicone grease with moderate viscosity and excellent performance can be prepared.

Future development direction of silicone grease consistency control

With the development of science and technology and the continuous emergence of new materials, the consistency control technology of silicone grease is also constantly improving. In the future, silicone grease consistency control will develop in the following directions:

1. Application of nanotechnology

Nanomaterials have unique physical and chemical properties. The introduction of nanomaterials into silicone grease formulas can significantly improve their performance. For example, the addition of nanomaterials such as nano-silicon dioxide and nano-alumina can improve the thermal conductivity and mechanical strength of silicone grease without significantly increasing its consistency.

2. Intelligent control technology

With the development of intelligent manufacturing technology, the preparation and consistency control of silicone grease will also develop in the direction of intelligence. By introducing intelligent control systems, real-time monitoring and automatic adjustment of silicone grease formula and consistency can be achieved, improving production efficiency and product quality.

3. Environmental protection and sustainable development

Against the background of environmental protection and sustainable development, the production and use of silicone grease also need to shift towards environmental protection. Developing low-toxic, pollution-free and degradable silicone grease formulas is one of the important directions for silicone grease consistency control in the future. For example, using plant-based silicone oil instead of traditional petroleum-based silicone oil can reduce its environmental impact while maintaining the performance of silicone grease.

Conclusion

The control of silicone grease consistency is a complex multi-factor process involving the viscosity of silicone oil, the type and amount of thickener, the use of functional additives, and the mixing and processing technology. By scientifically and rationally selecting and regulating these factors, silicone grease that meets the needs of specific applications can be prepared. In the future, with the development of nanotechnology, intelligent control technology and environmentally friendly materials, silicone grease consistency control technology will be further improved to provide better quality and more efficient lubrication and thermal conductivity solutions for various industries.

The control of silicone grease consistency is not only the adjustment of material formula, but also involves the optimization and control of the entire production process. Only through systematic and comprehensive research and practice can the precise control of silicone grease consistency be achieved, providing reliable technical support for various applications.

This article is sourced from the Internet and modified for reference only. If there is any infringement, please contact us to delete it.