The issue of silicone oil migration, whether in the form of gaseous volatilization or liquid spillage, is of great concern, although it is not always accompanied by specific problems. Based on effective analysis of its specific applications, we can design silicone formulas to meet these special application scenarios. The migration of silicone oil is usually determined by various factors such as the microstructure of the TIM material, the power density of the electronic components, thermal adsorption and structural design. Such problems can be solved by designing specialized materials for such uses. We will address the root causes, potential risks and mitigation measures for silicone oil migration.

TIM materials are composed of polymer resins and high thermal conductivity fillers, of which the thermal conductivity of the resin is about 0.1W/mK, the thermal conductivity of the filler is 1-1000W/mK, and the thermal conductivity of the TIM material is 1-15W/mK. The molecular chain structure and different cross-linking forms of the polymer resin system in TIM materials provide different physical forms for TIM materials. The polymer molecular chain segments form a network structure through entanglement.

In addition to cross-linked molecular clusters, the polymers in TIM materials also have some small molecules that are not linked to the molecular clusters by chemical bonds. If the molecular chains of these small molecules are short enough, they will not form entanglements with the molecular clusters, and will overflow from the main body of the TIM material in liquid form under certain conditions. Particularly small molecules will evaporate from the material in a gaseous state and accumulate on the surface of electronic components.

Most TIM materials use silicone resin systems because silicone polymers have excellent chemical stability and their physical properties do not change significantly with temperature, such as viscosity and modulus. This makes them particularly suitable for applications where significant temperature changes occur during operation due to high powers or power fluctuations.

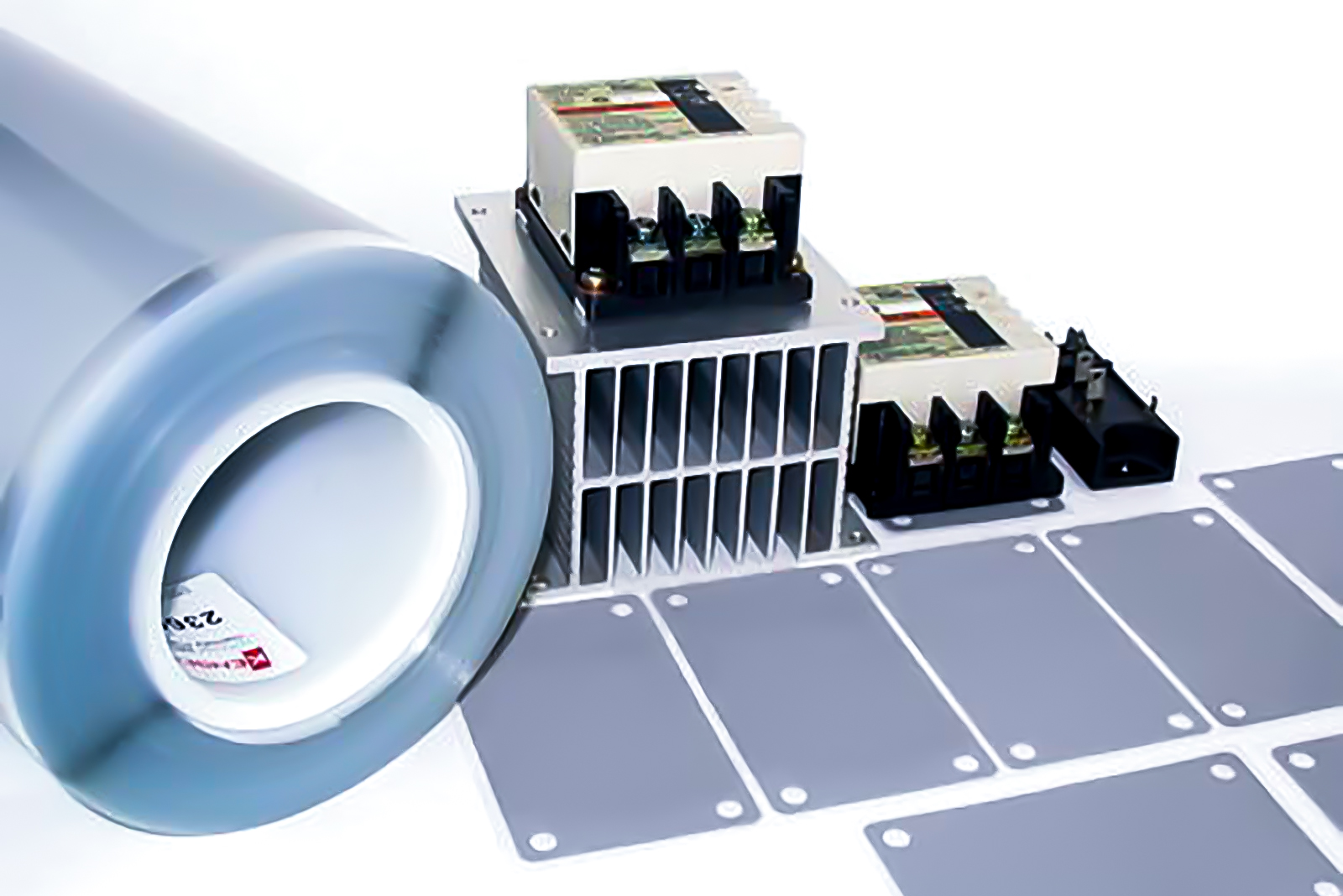

At present, thermal conductive materials such as thermal conductive silicone sheets are mostly made of thermal conductive powder filled with silicone as the matrix. Its advantages are low cost, good thermal conductivity, good softness, and resistance to 200° high temperature. Its disadvantage is that silicone oil will precipitate and siloxane will volatilize under long-term high temperature.

Hazards of low molecular weight volatilization and oil leakage of organic silicone

01. Security monitoring and camera equipment - volatile organic silicone components will condense on the mirror surface, pollute the lens, and affect the image clarity;

02. Hard disk (HDD) - the leaked silicone oil absorbs dust, causing damage to the read head and the recording film, and data cannot be read and written correctly;

03. Unpolymerized siloxane, the leaked siloxane migrates to the circuit board over time, absorbs dust, and may cause short circuits;

04. Under extreme conditions, the volatile siloxane will form an insulating layer of silicon dioxide, causing contact failure.

Product Features

1. The convenience of TGP3000SF/TGP8000SF ensures excellent thermal reliability in a variety of applications.

2. Silicone-free system, no siloxane volatilization (VOC) and oiling problems.

3. High compression ratio has low residual stress and excellent surface adhesion.

4. The product has natural viscosity and can be used with heat sources and heat sinks without additional adhesives.

5. The thickness range is 0.5mm to 5.0mm.