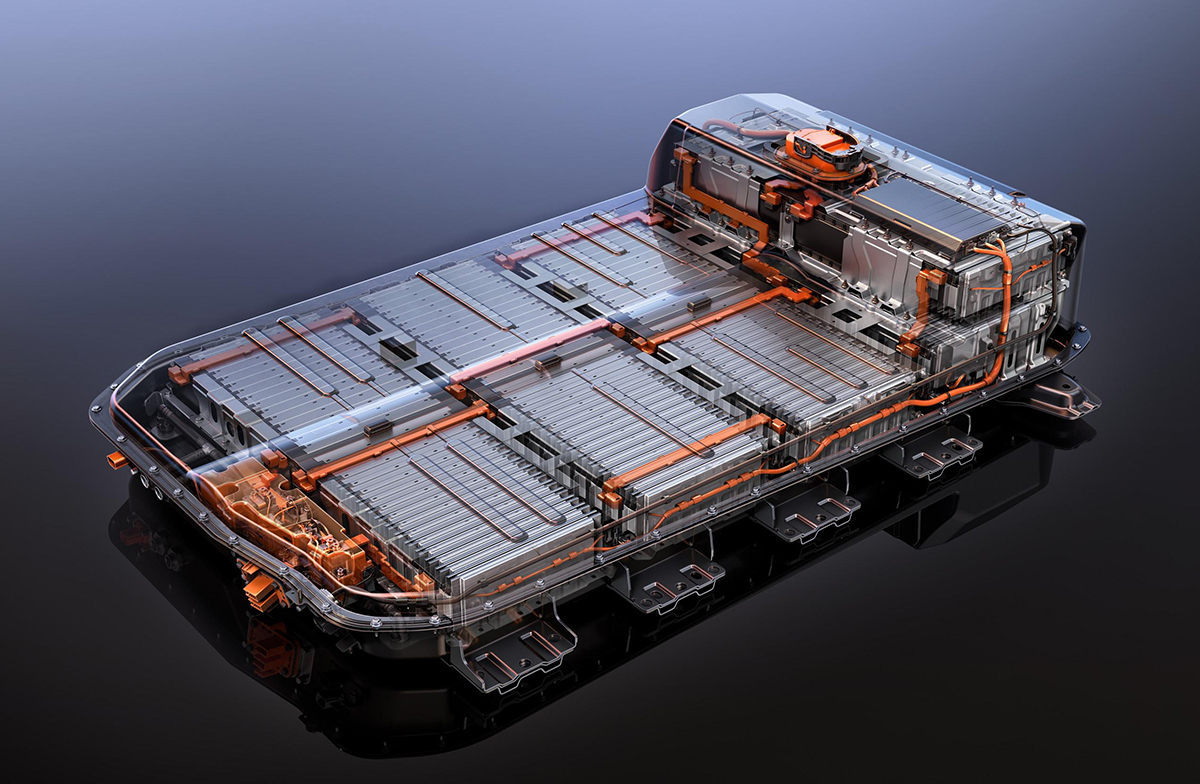

BMS battery system is commonly known as battery nanny or battery steward. It is mainly used to intelligently manage and maintain each battery unit, monitor the status of the battery, prevent the battery from overcharging and over-discharging, and extend the service life of the battery. The BMS battery management system unit includes a BMS battery management system, a control module, a display module, a wireless communication module, electrical equipment, a battery pack for powering electrical equipment, and a collection module for collecting battery information of the battery pack. The BMS battery management system is connected to the wireless communication module and the display module through the communication interface. The output end of the collection module is connected to the input end of the BMS battery management system. The output end of the BMS battery management system is connected to the input end of the control module. The control module is connected to the battery pack and the electrical equipment respectively. The BMS battery management system is connected to the server through the wireless communication module.

During the design and manufacturing process of BMS (Battery Management System, battery management system), some silicone thermal conductive materials are indeed used to optimize its thermal management performance. The selection of these thermal conductive materials is intended to improve the heat dissipation efficiency of the battery system and ensure that the battery remains in the appropriate temperature range during operation, thereby extending the battery life and improving the overall performance. Battery management system (BMS) is essential for modern electronic devices. It is like an intelligent brain, precisely regulating the energy flow of the battery. However, behind this, what silicone thermal conductive materials does BMS rely on to ensure the safety and stable performance of the battery? This is a fascinating question, because different manufacturers, product models and application scenarios may choose different materials.

In this issue, I am fortunate to learn some technical introductions and opinions sorted out by relevant industry experts online. The editor will take you to learn and review the mysterious veil of silicone thermal conductive materials and reveal the 7 major silicone thermal conductive materials commonly used in BMS systems. These materials, like the guardians of BMS, silently guard the safety and performance of the battery, making our lives more convenient and efficient.

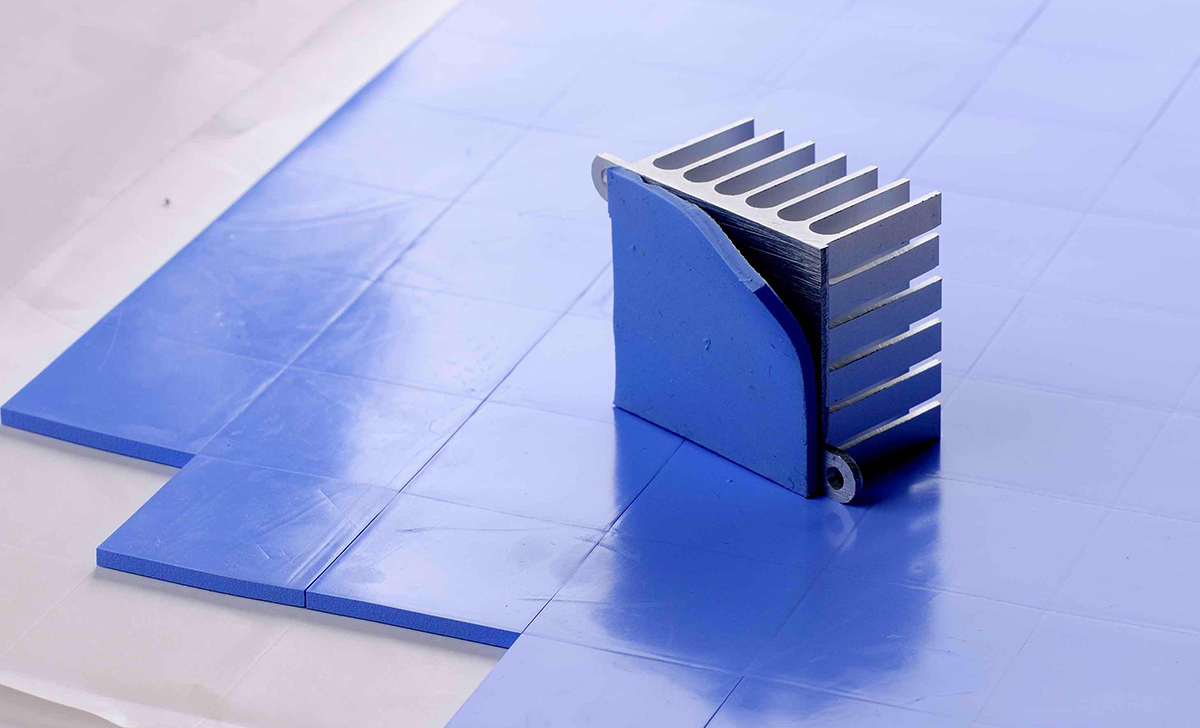

1. Thermally conductive silicone sheet:

Thermal conductive silicone sheet is a soft and elastic thermal management material that can fill the gap between battery cells or between batteries and heat dissipation components to effectively conduct heat, while also playing the role of insulation and shockproof.

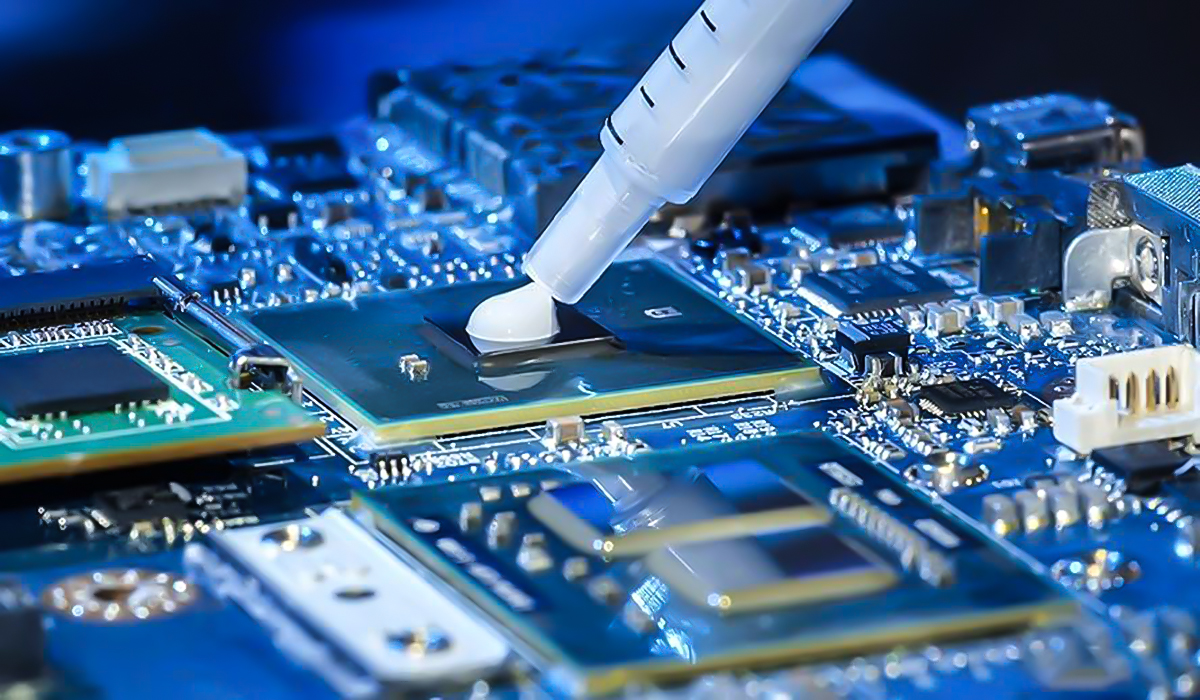

Between the battery management system components and the heat dissipation components, thermally conductive silicone grease can be applied to reduce contact thermal resistance, enhance heat conduction efficiency, and maintain good electrical insulation.

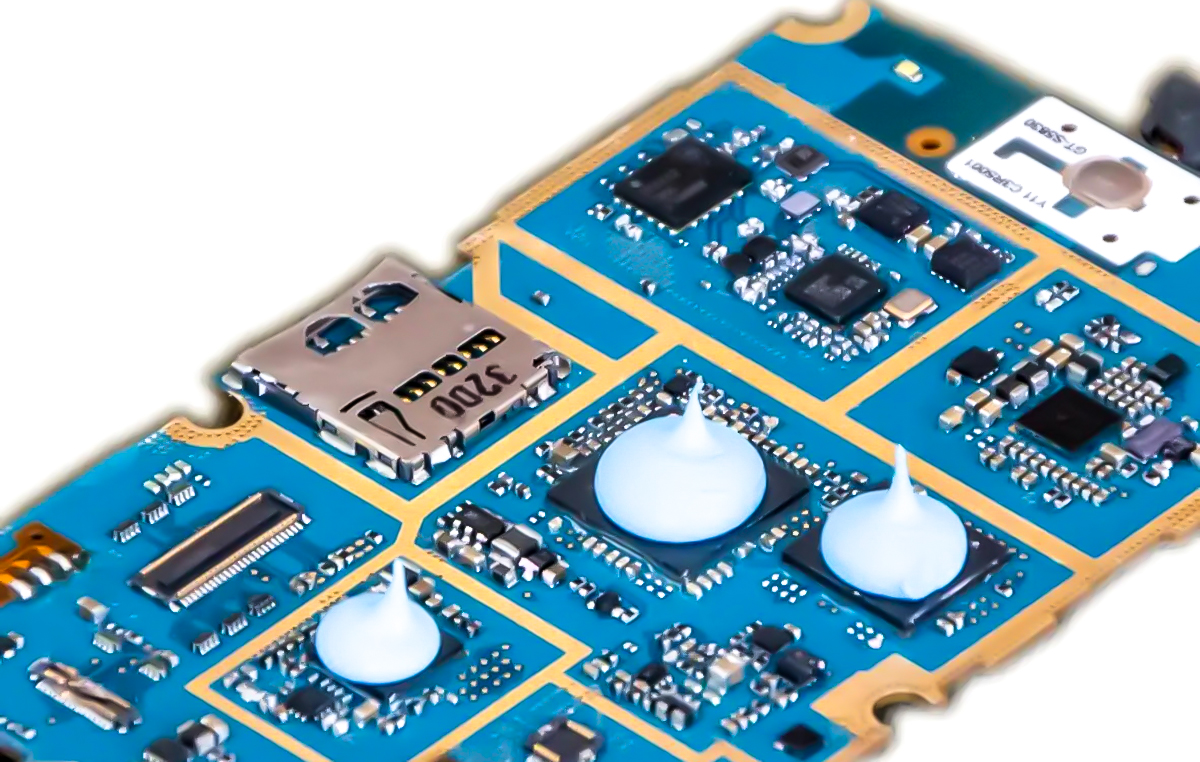

Thermal conductive silicone gel is a single-component thermally conductive compound. This material has high thermal conductivity, low thermal resistance and good electrical insulation properties. It can effectively distribute the heat inside the battery evenly to the entire battery pack to prevent local excessive temperature from causing battery performance degradation.

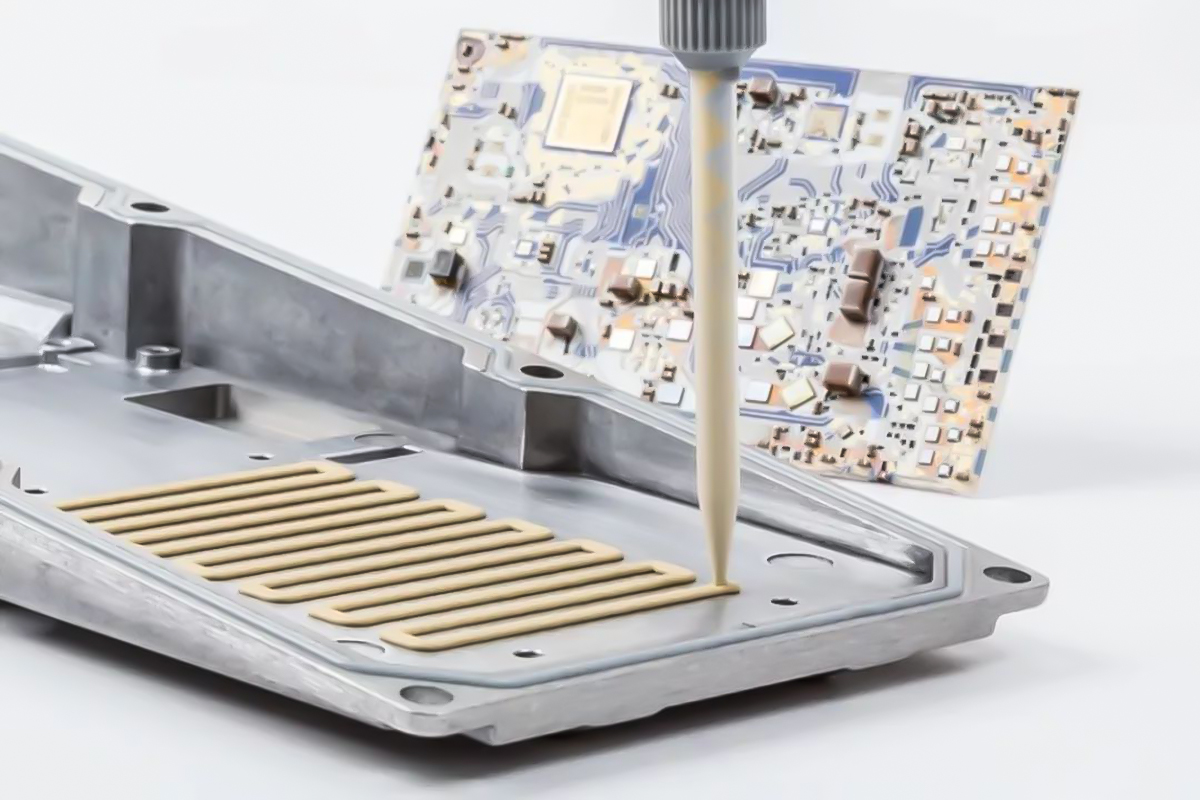

4. Two-component thermally conductive gel:

This material has excellent thermal conductivity, insulation, shock absorption and flame retardant properties. It is suitable for irregular gaps between battery modules to achieve heat transfer between the battery pack and the radiator, while forming an electrical insulation layer and a buffer layer to protect the battery pack and extend its service life.

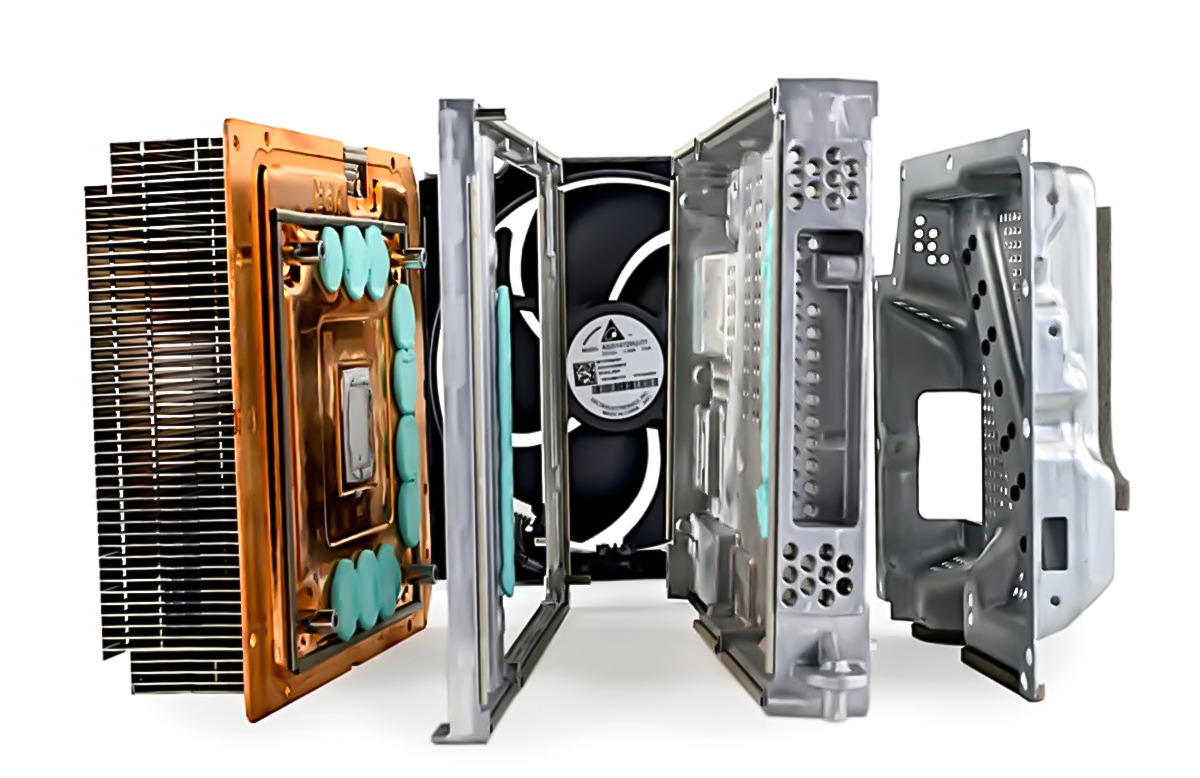

Thermal conductive insulating sheet can effectively conduct heat out of BMS and reduce the operating temperature of battery components, thereby improving the stability of the battery and extending its service life. During the operation of BMS, the battery module will generate heat. If it cannot be dissipated in time, it may cause battery performance degradation or safety hazards. The thermal conductivity of the thermally conductive insulating sheet helps to solve this problem and keep the battery within a suitable operating temperature range.

The thermally conductive insulating sheet not only has a thermal conductivity function, but also has excellent electrical insulation performance. In BMS, good insulation needs to be maintained between components to prevent safety problems such as current leakage or short circuit. Thermally conductive insulating sheet can provide an effective insulation barrier to ensure the electrical safety of BMS.

Thermal conductive adhesive has excellent thermal conductivity. During the operation of BMS, the battery module will generate heat. If it cannot be dissipated in time, it may cause battery performance degradation or even cause safety problems. Thermally conductive adhesive can effectively conduct the heat generated by the battery module, maintain the stability of the battery and extend its service life.

Secondly, thermally conductive adhesive also has strong bonding ability. It can be firmly bonded to a variety of materials (such as metals, ceramics, plastics, etc.) inside the BMS to ensure a solid connection between components. This bonding ability not only helps to improve the overall structural strength of the BMS, but also prevents loosening or damage to components caused by vibration or impact.

In addition, thermally conductive adhesives also have flame retardant, moisture-proof, shock-proof, and insulating properties, which further enhance the safety and reliability of the BMS. Flame retardant properties can reduce the risk of fire to a certain extent, while moisture-proof and shock-proof properties help protect the BMS from harsh environmental conditions.

Silicone thermally conductive potting glue is a soft, elastic, and surface-adhesive silicone elastomer formed by addition curing reaction at room temperature, and has excellent electrical insulation properties. For battery management system electronic modules that require dustproof, waterproof, shock-resistant and good heat dissipation performance, thermally conductive silicone potting glue can be used for overall packaging, which not only protects internal components but also effectively conducts heat.

In BMS, the main function of these silicone thermal conductive materials is to improve the heat dissipation efficiency of the battery and ensure that the battery works within a safe temperature range, thereby extending the battery life and improving the overall performance of electric vehicles. It is worth mentioning that the Nofeng NF series thermal conductive materials have been widely used in BMS due to their excellent thermal conductivity and various physical properties. They can effectively and quickly conduct the heat generated by the battery and BMS, thereby ensuring the stable performance of the battery.

These silicone thermal conductive materials can be customized with different hardness, thickness, thermal conductivity, pressure resistance level, flame retardant level and temperature resistance range according to actual application requirements to meet the thermal management requirements of different BMS systems.

It should be noted that the design and manufacture of BMS is a complex process. In addition to the selection of thermal conductive materials, multiple factors such as battery type, capacity, operating voltage, and working environment need to be considered. Therefore, the specific selection and use of thermal conductive materials should be designed and optimized by professional engineers according to actual needs.

In addition, with the continuous development of science and technology, new thermal conductive materials and technologies are constantly emerging. Therefore, for BMS manufacturers, continuing to pay attention to new technologies and new materials in the field of thermal conductive materials and continuously optimizing the thermal management performance of products is also an important means to improve product competitiveness and market share.

Disclaimer: The content and pictures of this article are written by the resident author or reprinted from relevant learning and exchange websites. The article is only used for learning and exchange among peers and popularization of science. If there is any infringement of the content or other violations, please contact this website for processing.