Silicone Mini Classroom-Synthesis and Technology of Silicone Pressure-Sensitive Adhesive

Silicone pressure-sensitive adhesive generally refers to pressure-sensitive adhesive with silicone polymer as the main body, or acrylic and silicone-modified rubber pressure-sensitive adhesive modified by silicone polymer. Compared with traditional acrylic pressure-sensitive adhesives and rubber-type pressure-sensitive adhesives, it has excellent chemical resistance, water resistance, oil resistance, solvent resistance, high temperature resistance, low temperature resistance, thermal degradation resistance, oxidative degradation resistance, etc., and can Bonding with a variety of difficult-to-bond materials such as unsurface-treated polyolefins (BOPP, PET, PE, etc.) fluoroplastics, polyimide, and polycarbonate.

Regarding the synthesis and application of silicone pressure-sensitive adhesives, silicone pressure-sensitive adhesives are widely used in materials in industry, medical and daily life. Adhesion and weather resistance play an important role in many fields. Silicone pressure-sensitive adhesives The synthesis process has a great impact on the performance characteristics of the material, which is related to the production quality. The following editor will explain the synthesis and process as well as the current development status of pressure-sensitive adhesives in my country.

1. Raw material selection

The synthesis of silicone pressure-sensitive adhesive mainly involves raw materials such as silane monomers, catalysts, cross-linking agents, and plasticizers. Silane monomer is the basis for synthesizing silicone pressure-sensitive adhesive, and its selection directly affects the performance of the final product. Commonly used silane monomers include methyltrimethoxysilane, ethyltrimethoxysilane, etc. Catalysts are used to promote the hydrolysis and polycondensation reactions of silane monomers. Commonly used catalysts include ammonia, acetic acid, etc. Cross-linking agents are used to improve the cohesive strength and heat resistance of silicone pressure-sensitive adhesives. Common cross-linking agents include methyltrimethoxysilane, methyltriethoxysilane, etc. Plasticizers are used to adjust the viscosity and flexibility of silicone pressure-sensitive adhesives. Commonly used plasticizers include dibutyl phthalate, dioctyl phthalate, etc.

2. Reaction conditions

The synthesis of silicone pressure-sensitive adhesive is usually carried out under certain temperature and pressure. Temperature is an important factor affecting reaction rate and product performance, and is generally controlled between room temperature and 100°C. Pressure mainly affects the stability of the reaction system and the purity of the product, and is usually carried out under normal pressure or slightly higher than normal pressure. In addition, reaction time is also a key factor affecting product performance and needs to be adjusted according to specific reaction conditions and raw material characteristics.

3. Synthesis steps

Mix the silane monomer, catalyst, cross-linking agent and other raw materials evenly according to a certain proportion to obtain the prepolymer.

Under a certain temperature and pressure, the prepolymer undergoes hydrolysis and polycondensation reactions to generate silicone pressure-sensitive adhesive.

During the reaction process, add an appropriate amount of plasticizer as needed to adjust the viscosity and flexibility of the silicone pressure-sensitive adhesive.

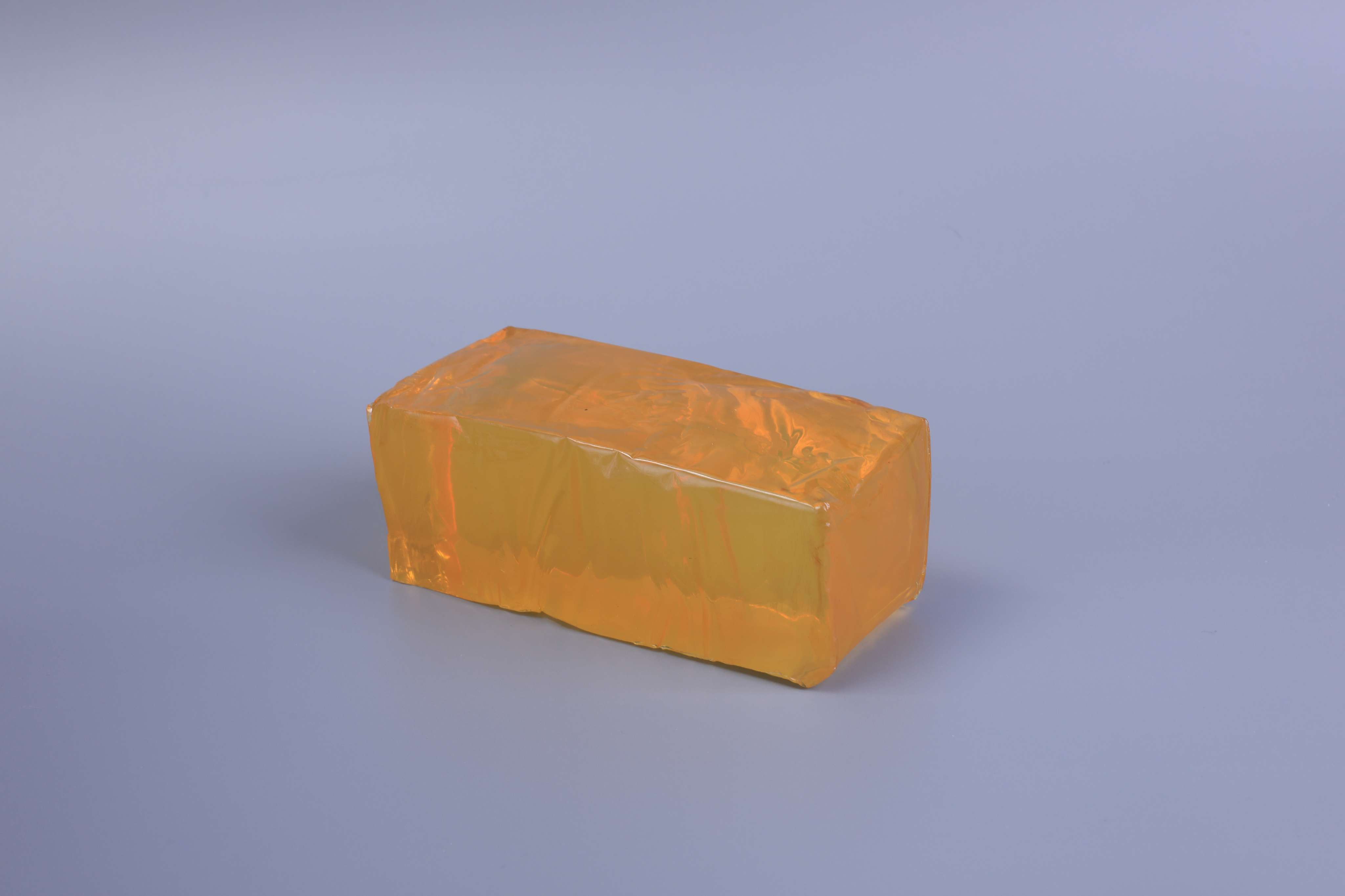

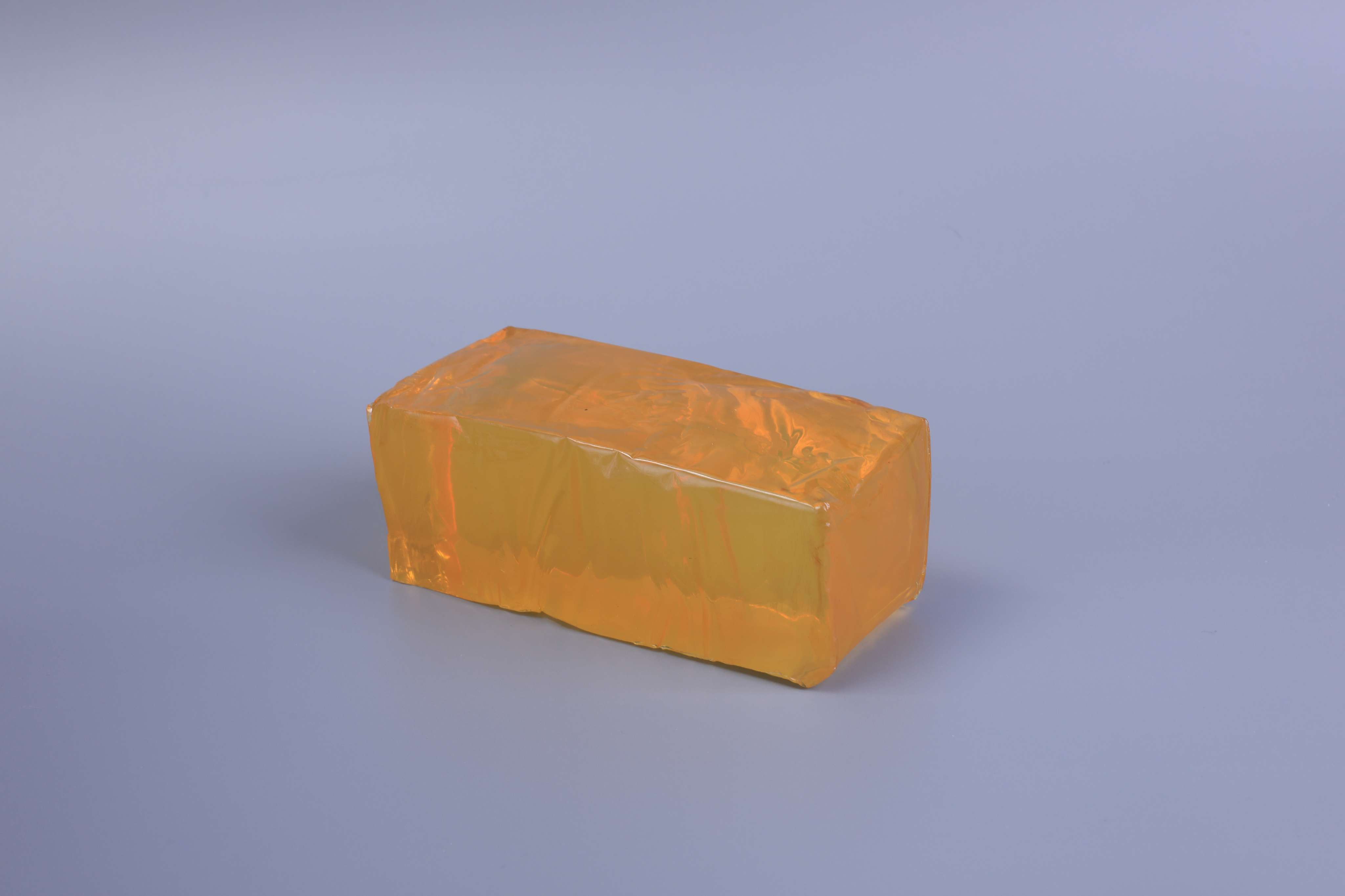

After the reaction is completed, the product is subjected to post-processing, such as filtration, defoaming, curing, etc., to obtain the final silicone pressure-sensitive adhesive.

4. Follow-up processing

The synthesized silicone pressure-sensitive adhesive requires a series of subsequent treatments to ensure its stable performance and ease of use. First, the product needs to be filtered to remove impurities and unreacted raw materials. Secondly, through degassing treatment, the bubbles in the product are removed and its appearance quality and adhesion performance are improved. Finally, the product is cured as needed to improve its cohesive strength and heat resistance.

5. Development status

The synthesis process of silicone pressure-sensitive adhesive involves a lot. Through reasonable synthesis process, silicone pressure-sensitive adhesive with stable performance can be obtained, and it also provides more choices for the use of silicone pressure-sensitive adhesive in different industries.

my country’s silicone pressure-sensitive adhesives mainly rely on imports, and domestic research and development is still in its early stages. Silicone pressure-sensitive adhesives are divided into solvent-based and heat-curing types. Solvent-based silicone pressure-sensitive adhesives can be used after heating or leaving them naturally for a period of time to allow the solvent to evaporate, and then become pressure-sensitive adhesives. However, this type of pressure-sensitive adhesive can be dissolved by solvents. Heat-curing silicone pressure-sensitive adhesives usually need to be heated to more than 100 degrees to cure and form pressure-sensitive adhesive properties. If you need to use a release film, use ordinary pressure-sensitive adhesive release film. Different silicone pressure-sensitive adhesives have different heat resistance properties, and the ones with high temperature resistance can reach more than 300 degrees Celsius. The usual solid content of silicone pressure-sensitive adhesives is generally between 10% and 60%. The range of viscosity (viscosity) is very adjustable (the consistency is not necessarily proportional to the solid content), and the low one can be several hundred. CPS (centipoise = mpas), and the high one can reach millions of CPS. Therefore, manufacturers can provide different models according to needs to meet the requirements of different construction techniques, such as single coating, mesh coating, dip coating, Scratching, brushing, shower coating, etc. Silicone pressure-sensitive adhesives usually contain flammable and toxic solvents, such as toluene, xylene, ethyl acetate, solvent gasoline, petroleum ether, etc., which need to be managed as dangerous goods during storage, transportation and use.