Thermal conductive silicone sheet is a thermally conductive medium material synthesized through a special process, using silica gel as the base material, adding various auxiliary materials such as metal oxides.

Thermal conductive silicone rubber is a polymer composite material that uses silicone resin as a bonding material and is filled with thermally conductive powder to achieve thermal conductivity. Contains the following materials: silicone resin (basic raw material) insulating and thermally conductive fillers: alumina, magnesium oxide, boron nitride, aluminum nitride, beryllium oxide, quartz, etc. Silicone plasticizers flame retardants: magnesium hydroxide, aluminum hydroxide inorganic Colorant (color differentiation) Cross-linking agent (bonding performance requirements) Catalyst (process molding requirements)

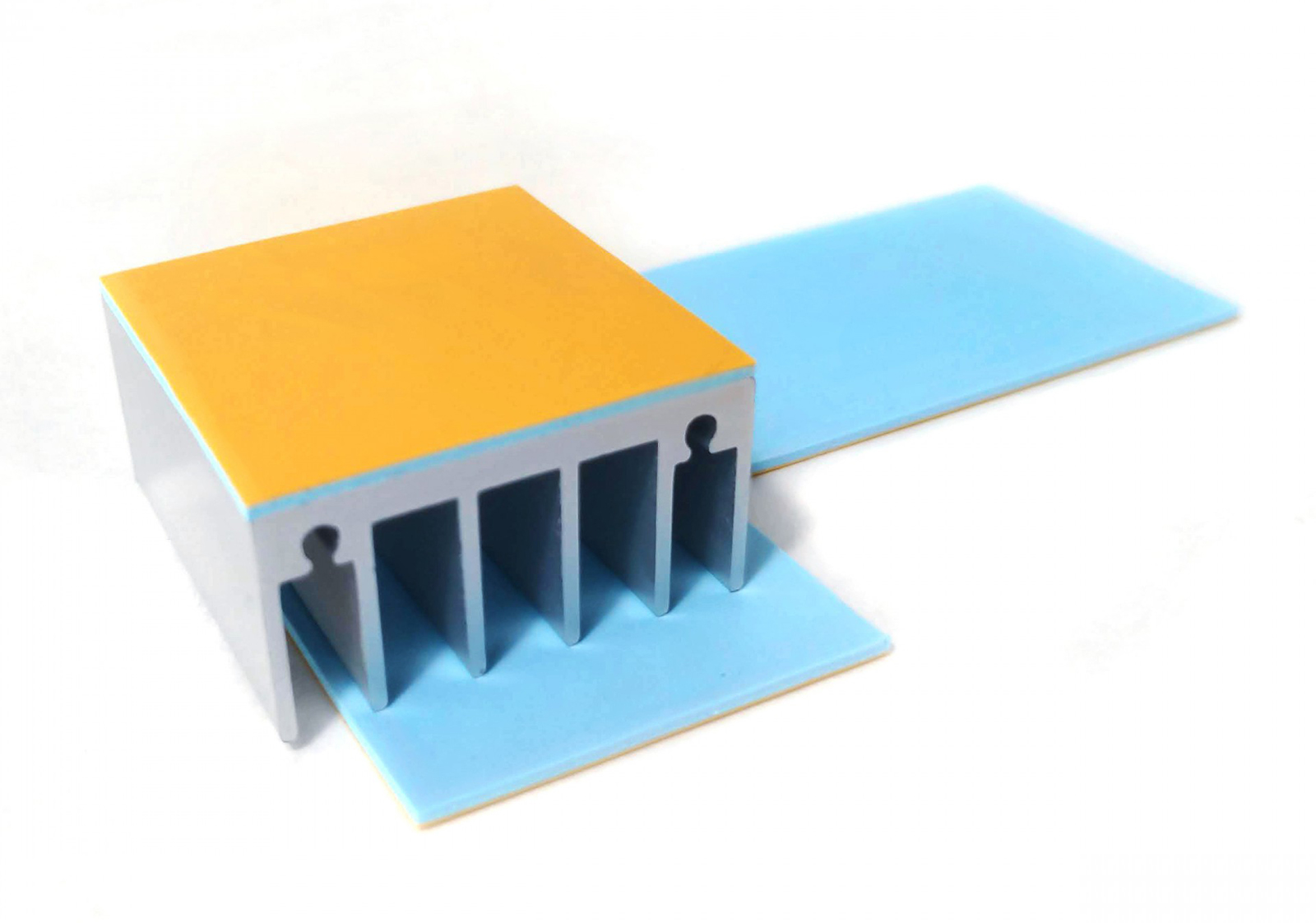

The thermally conductive silicone sheet only plays the role of heat conduction, forming a good heat conduction path between the heating element and the heat dissipation device, and together with the heat sink, structural fixings (fan), etc., it forms a heat dissipation module.

2. Why use thermally conductive silicone sheet?

The main purpose of selecting thermally conductive silicone sheets is to reduce the contact thermal resistance between the heat source surface and the contact surface of the heat sink device.

The thermally conductive silicone sheet can well fill the gap between the contact surfaces and squeeze the air out of the contact surface. Air is a poor conductor of heat and will seriously hinder the transfer of heat between the contact surfaces; with the addition of the thermally conductive silicone sheet, the contact can be made Better full contact between the surfaces, truly face-to-face contact, and the temperature reaction can achieve as small a temperature difference as possible.

Thermal conductive silicone sheet has the following advantages over thermal conductive silicone grease and thermal double-sided tape:

1) The range and stability of thermal conductivity

2) Bridging the process tolerances on the structure and reducing the process tolerance requirements for radiators and heat dissipation structural parts

3) Insulation performance

4) Shock absorption and sound absorption effect

5) Convenience of installation, testing and reusability

4. The uses and applications of thermally conductive silicone sheets

Conductive silica gel is a special silica gel material that has good conductive properties under specific conditions. Conductive silica gel electrode sheets are made of conductive silica gel and have excellent conductivity and good flexibility, so they are widely used in many fields.

The functions of conductive silica gel electrode sheets are mainly reflected in the following aspects: First, they can be used as battery electrodes and have good electrochemical properties. Secondly, conductive silicone electrode sheets can be used in various sensors to improve the sensitivity and accuracy of the sensors. In addition, conductive silicone electrodes can also be used in biomedical fields, such as pacemakers, insulin pumps, etc., to monitor and treat physiological signals in the human body.

Conductive silicone electrode sheets are used in a wide range of applications, including electronics, medical, biology, energy, etc. In electronic products, such as smartphones, tablets, etc., conductive silicone electrode sheets can be used for wireless charging and touch screen technology. In the medical field, conductive silicone electrode sheets can be used in monitoring equipment such as electrocardiogram and electroencephalogram. In the energy field, conductive silica gel electrode sheets can be used in the manufacture of new energy equipment such as lithium-ion batteries and fuel cells.

The manufacturing process of conductive silica gel electrode sheets mainly includes the following steps: First, the conductive powder is evenly mixed into the silica gel matrix to make conductive silica gel. Secondly, conductive silicone is made into electrode sheets through specific molds and processes. Finally, the conductive silicone electrode sheet is surface treated to improve its conductive performance and stability.

Conductive gel electrode sheets have many advantages, such as good conductivity, flexibility, high and low temperature resistance, corrosion resistance, etc. However, there are also certain disadvantages, such as conductive properties that may decrease over time and durability that needs to be improved. In order to overcome these shortcomings, researchers are constantly working to improve the performance of conductive silicone electrode sheets.

This article and pictures come from the Internet. If there is any infringement, please contact us to delete it. For learning reference only.