Introduction to amino silicone oil

Amino silicone oil is the basic ingredient mainly used in textile softening agents. It has the best adsorption, compatibility and easy emulsification. Using a mixer or homogenizer, aminosilicone fluids are easily emulsified by appropriate surfactants into stable, transparent microemulsions. It can be used alone or combined with other silicone or organic softeners to form a special softening finishing agent, suitable for the softening finishing of various textiles.

Amino silicone oil market overview

Organopolysiloxanes began to be used as fabric softeners in the 20th century, and have experienced the development process from polydimethylsiloxane as the main body to modified polysiloxane organosilicon compounds. In the early 1950s, the American Dow Corning Company discovered that the combination of hydrogen-containing polysiloxane and polydimethylsiloxane not only has a waterproof effect but also has a soft feel. This dimethyl silicone oil product is the first generation of silicone fabric softener. By the 1960s, Dow Corning applied for hydroxyl silicone oil patents one after another and published emulsion polymerization reports and application reports of hydroxyl emulsions in fabric finishing. These are all second-generation silicone fabric softeners. Due to the single function of the second-generation softener and the problems of easy demulsification and oil bleaching, the third-generation silicone softener was produced in response to the requirements of the times, that is, modified silicone softener, which introduces amino and epoxy groups through the side chain. , polyether, hydroxyl and other groups, which greatly improve the washability, shrinkage resistance, hydrophilicity, etc. of the fabric.

Amino silicone oil is a typical representative of the third generation of silicone softeners. The active groups of amino silicone oil can combine more strongly with natural fibers, chemical fibers and blended fabrics. At the same time, due to the disadvantages of amino silicone oil, such as yellowing, increased hydrophobicity of fabrics, and uneven distribution of amino groups, research on the modification of amino silicone oil has been promoted. Amino silicone oils with reactive multifunctional groups distributed on the side chains and terminals and which are easy to emulsify have appeared one after another. As well as modified products such as amino-containing block copolymers formed by modified polysiloxane and other polymers.

China’s amino silicone oil industry market research report covers statistics of historical market data in the past five years and forecasts of future market capacity growth trends. In 2022, the global amino silicone oil market size will reach 3.088 billion yuan (RMB), and China's amino silicone oil market size will reach x.x billion yuan. The report predicts that the global amino silicone oil market will reach 4.15 billion yuan by 2028, and the compound annual growth rate of the amino silicone oil market during the forecast period is estimated to be 5.04%.

By product type, the amino silicone oil industry can be subdivided into amine value (>06), amine value (03-06), and amine value (01-03). According to the end application classification, amino silicone oil can be used in areas such as clothing softener, leather smooth agent, release agent, paper softener and so on. From a segmentation perspective, the research scope of the report includes market sales, share proportions and growth trends in each segment.

Mainstream companies in China's amino silicone oil industry include Runhe, Wacker, Shin-Etsu, ACC Silicones, Bluestar, Jiangxi xinghuo, Ruiguang, Momentive, Iota Silicone Oil, and KCC Basildon. The report covers the analysis of the development profile, market share, revenue status of major companies, and the market share of the top three companies in terms of business scale in 2022.

Application scope of amino silicone oil

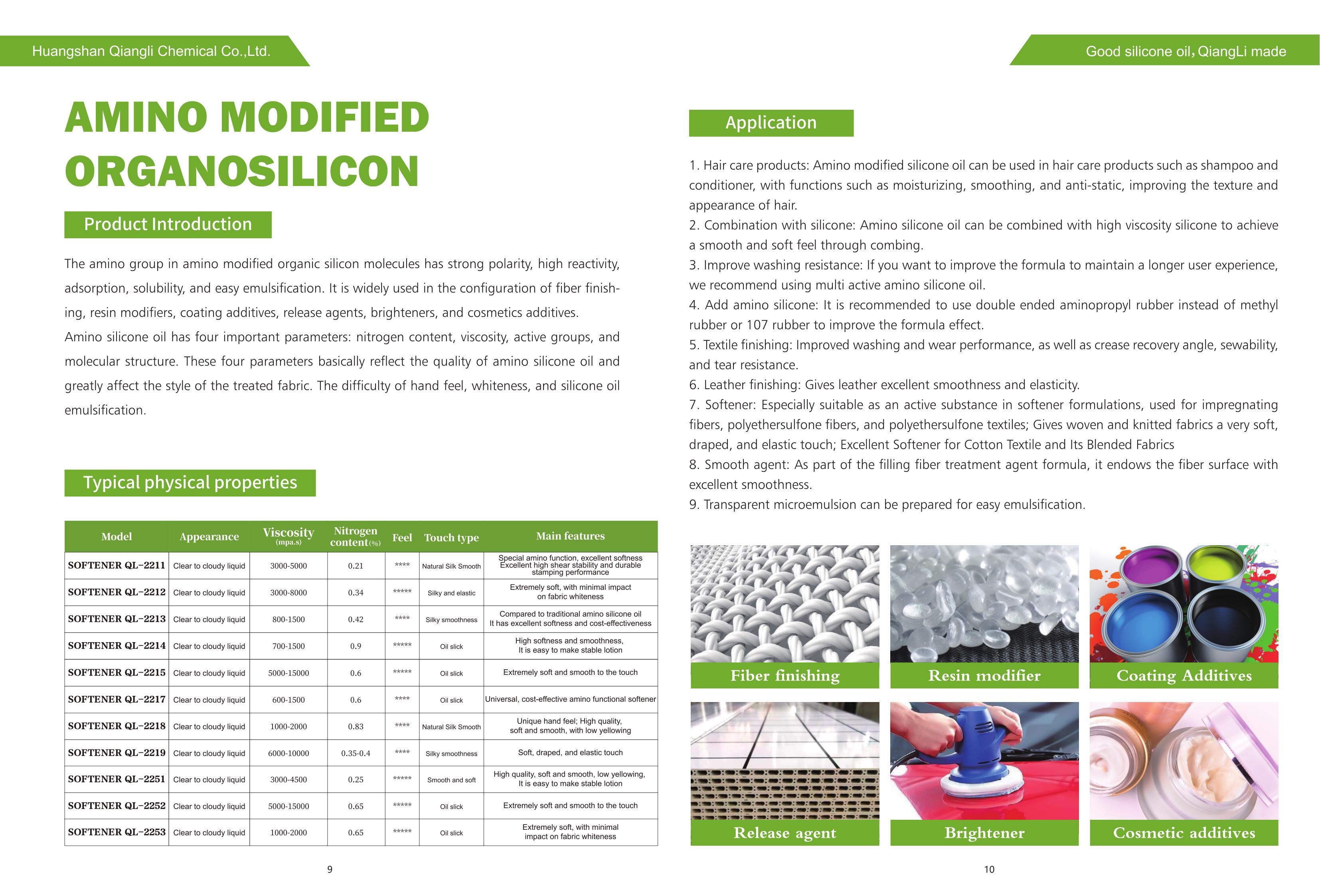

The amino group in the amino silicone oil molecule has strong polarity, high reactivity, adsorption, compatibility and easy emulsification. It is widely used as fiber finishing agent, resin modifier, coating additive, brightener and cosmetic additive, etc.

1. Amino silicone oil is used as finishing agent for textile fibers

The amino group in the amino silicone oil molecule can interact with the hydroxyl and carboxyl groups on the fiber surface, forming a very strong orientation and adsorption with the fiber, which reduces the friction coefficient between fibers and makes fiber products comfortable when worn. Amino silicone oil is an important softener for natural fibers such as cotton, linen, silk, and woolen products, and synthetic fibers such as polyester, nylon, and polyacrylonitrile. It is an indispensable raw material for high value-added and high-functional fiber products.

2. Amino silicone oil can be used as polymer modifier

Amino silicone oil reacts with the functional groups of organic polymers to introduce siloxane into the organic polymer, thus giving the polymer new properties. For example, amino silicone oil can be used as a monomer for organic polymer synthesis or melt-mixed with polymers to modify the resin. There are thermoplastic resins such as polyamide, polyimide, polyurethane, and polyester, and thermosetting resins such as epoxy and phenolic resin. For example, during the condensation of aromatic tetracarboxylic acid, anhydride, and amino compounds, the silicone-modified polyimide prepared by adding modified silicone oil with aminopropyl groups at both ends has siloxane links introduced into its molecules. , has very good adhesion to substrates such as semiconductor contacts and glass, and is widely used as protective films for semiconductors. Oxygen resin plastic encapsulation materials used for integrated circuits often cause cracking of the encapsulating resin, passivation of the silicon wafer surface, film cracking and interface breakage due to internal stress. For example, adding aminopropyl-modified silicone oil and epoxy resin at both ends Comprehensive modification can improve the softness, toughness and yield of plastic packaging materials, and reduce its internal stress. When synthesizing polyamide, adding amino-terminated modified silicone oil to caprolactam and cocondensation of equal molecules of adipic acid, the resulting silicone-modified polyamide can significantly improve the low-temperature impact strength without affecting the finishability of the product.

3. Amino silicone oil is used as coating additive

As a paint additive, amino silicone oil can effectively prevent color unevenness and wrinkles and increase the brightness. The polyurethane coating used for decorative panels has low film hardness and is easy to adhere to each other when stacked together. The film is easily damaged when pulled apart. Adding amino silicone oil can make the film have very good anti-war properties.

4. Amino silicone oil is used as release agent, cosmetic additive, softener and brightener.

The development history of amino silicone oil

The development history of silicone softeners can be traced back to the 1940s. As early as 1940, people were trying to impregnate fabrics with dimethyldichlorosilane in order to achieve some kind of waterproofing effect. However, during use, dimethyldichlorosilane will release hydrogen chloride gas that is harmful to the human body and fabrics. In 1945, people impregnated fabrics with an alkaline solution of sodium methylsilanolate and found that the fabrics had good waterproofing effects after being treated with weak acid and dried at 110°C to 120°C. However, the highly alkaline impregnating solution had adverse effects on the fabrics. adverse effects. Therefore, neither of the above two technologies has been adopted by the textile industry. After the emergence of hydrogenated silicone oil around the 1950s, researchers from Dow Corning Company used hydrogenated silicone oil emulsion to finish fabrics and achieved good waterproofing effects. However, the waterproof film formed by hydrogenated silicone oil on the surface of the fabric is hard, brittle, and easy to fall off. By adding methyl silicone emulsion and hydrogenated silicone emulsion for blending and finishing, the waterproof membrane formed is soft and feels good. This was a discovery of practical significance, which sparked research interest in silicones as fabric softeners. The development of polysiloxanes in the past 50 years, especially the emergence of reactive and functional polysiloxanes, has led to a variety of silicone softeners, which are widely used in fiber and fabric softening, spinning oils, and hair conditioners. and the compounding of household detergents.