What are the application fields of silicone resin? Today, various industries are developing rapidly, and many industries will try the application of various materials. Silicone resin is a very excellent material. It has been around for decades. Silicone resin is also continuously used in various fields. It is a widely used material. The editor will take you to understand it. Bar.

1. Polymer products: linear and bulky polymers, including supporting catalysts, cross-linking agents, additives, etc., are the main application varieties of silicone resins;

2. Large-scale application: in the electric power industry, mold manufacturing, textile finishing, construction industry, automobile, solar energy, communications, medical beauty, kitchen and bathroom, etc., its applications are widespread and ubiquitous;

3. Key applications: multiple varieties, small batches, multiple batches, suitable for electronic and electrical manufacturing, communications industry, aerospace and military industry, core equipment manufacturing, etc., and is one of the key materials essential for high-end manufacturing;

4. Sustainability: It provides sustainable and applicable new materials for the upgrading of consumer, Internet, smart grid, artificial intelligence, new energy, electric power and other industries.

Silicone resin is mainly used as insulating paint (including varnish, enamel, color paint, impregnating paint, etc.) to impregnate H-class motors and transformer coils, and is used to impregnate glass cloth, glass cloth silk and asbestos cloth to make motor bushings and electrical insulation Winding etc.

Using silicone insulating paint to bond mica can produce large-area mica sheet insulation materials, which can be used as the main insulation of high-voltage motors.

In addition, silicone resin can also be used as heat-resistant and weather-resistant anti-corrosion coatings, metal protective coatings, waterproof and moisture-proof coatings for construction projects, release agents, adhesives and secondary processing into silicone plastics for use in the electronics, electrical and defense industries. On the market, it is used as semiconductor packaging materials and insulating materials for electronic and electrical components.

Usually, various mixtures of methyltrichlorosilane, dimethyldichlorosilane, phenyltrichlorosilane, diphenyldichlorosilane or methylphenyldichlorosilane are used in the presence of organic solvents such as toluene. It is decomposed by adding water at a lower temperature to obtain acidic hydrolyzate.

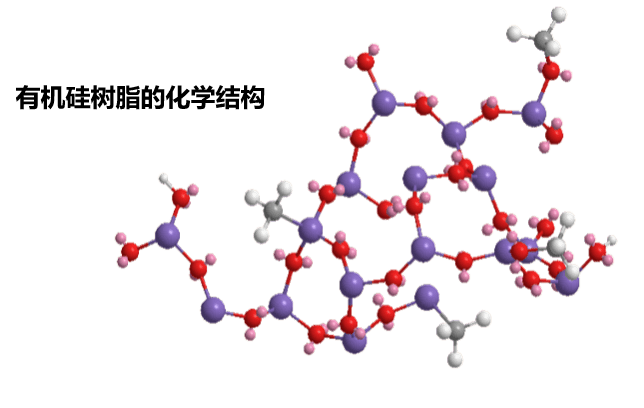

The initial products of hydrolysis are mixtures of cyclic, linear and cross-linked polymers, often containing a considerable number of hydroxyl groups.

The hydrolyzate is washed with water to remove the acid, and the neutral primary condensation polymer is thermally oxidized in the air or further polycondensed in the presence of a catalyst, and finally forms a highly cross-linked three-dimensional network structure.

Silicone resin is a thermosetting plastic. One of its most outstanding properties is its excellent thermal oxidation stability. After heating at 250°C for 24 hours, the weight loss of silicone resin is only 2 to 8%.

Another outstanding property of silicone is its excellent electrical insulation properties, which can maintain its good insulation properties over a wide temperature and frequency range.